The aviation industry is always seeking advancements to improve efficiency and reduce carbon emissions. The former is due to the never-ending quest for profit, while the latter helps airlines maintain their social license to operate. Less cynically, more efficient technologies are better for the environment, too.

One of the latest innovations in this space is a new sharkskin-like film applied to airliners to help cut drag. Inspired by nature itself, it’s a surface treatment technology that mimics the unique characteristics of sharkskin to enhance aircraft efficiency. Even better, it’s already in commercial service!

From The Ocean To The Sky

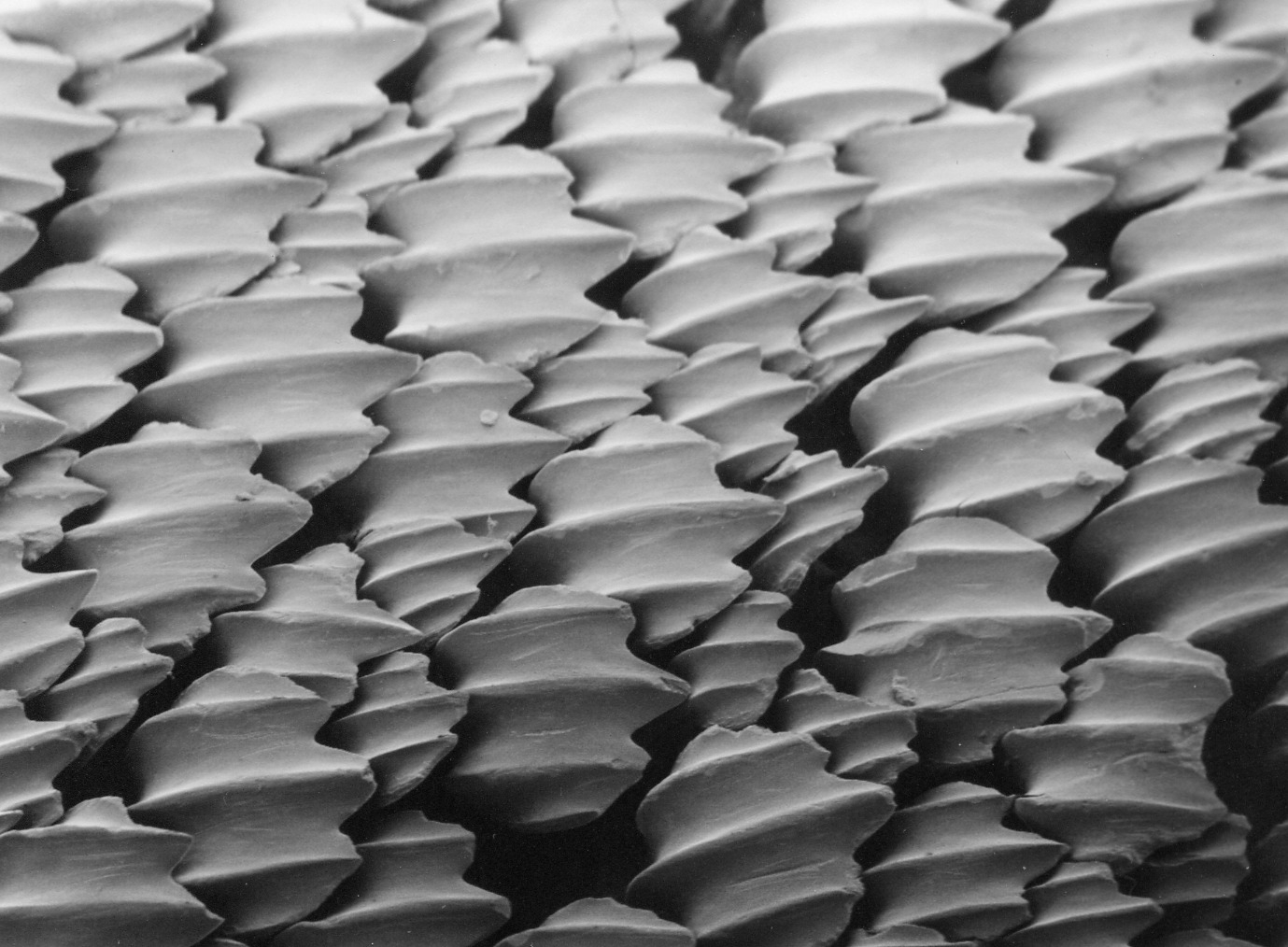

The riblets, as seen on the scales, or “denticles,” of a shark’s skin. The riblets are the ridges seen here, aligned left-to-right. Credit: Pascal Deynat/Odontobase, CC BY-SA 3.0

" data-medium-file="https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions.jpg?w=400" data-large-file="https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions.jpg?w=800" decoding="async" class="size-full wp-image-610328" src="https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions.jpg" alt width="800" height="588" srcset="https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions.jpg 1379w, https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions.jpg?resize=250,184 250w, https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions.jpg?resize=400,294 400w, https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions.jpg?resize=800,588 800w" sizes="(max-width: 800px) 100vw, 800px">Nature often holds the keys to groundbreaking technological advancements. What it has figured out over millions of years can teach us a lot today. In this regard, the shark has skin unlike any other marine creature. Evolution has bestowed upon it a somewhat rough and ribbed skin. This complex natural structure is credited with reducing drag as the shark navigates through water.

Two major components of sharkskin play into this role. The first is a complex interaction with the passive way the shark’s scales respond to water flows. The second is the “riblet” features on the scales of the shark’s skin. This feature has been explored as a potential drag-saving tool for everything from swimsuits to cars. Riblets are essentially like small keels on the skin, which are aligned with the flow direction of the water flowing over the shark’s body.

Typically, you’d expect the extra wetted surface area created by the riblets to increase drag, but they do quite the opposite. The mechanisms are still not fully understood, but research has revealed some of the secrets involved. Under typical turbulent flow during swimming, vortices form above the riblet surface, only interacting with the tips of them. This leaves a lower-velocity channel in the valleys between the riblets, reducing sheer stresses in the fluid in this area over the majority of the riblet surface. As a whole, vortex translation across the skin surface is also reduced by the riblet structures. This reduces turbulence overall by virtue of reducing vortexes bursting, tangling, and otherwise negatively interacting with each other.

Commercialization

Lufthansa expects to make major savings by using the AeroSHARK film.

" data-medium-file="https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions.png" data-large-file="https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions-1.png?w=800" decoding="async" class="wp-image-610330 size-medium" src="https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions.png" alt width="400" height="177" srcset="https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions-1.png 1300w, https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions-1.png?resize=250,110 250w, https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions-1.png?resize=400,177 400w, https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions-1.png?resize=800,353 800w" sizes="(max-width: 400px) 100vw, 400px">Engineers at Lufthansa Technik and BASF saw an opportunity to translate the hydrodynamic marvel of riblets into the aerospace realm. The result of that work is AeroSHARK, an adhesive riblet film designed to reduce fuel consumption, and in turn, emissions from aircraft.

This innovative film, though subtle in appearance, is poised to make a significant difference in the aviation world. The surface of AeroSHARK boasts millions of prism-shaped “riblets”, each no more than 50 micrometers high, or approximately 2/1000ths of an inch. When applied to an aircraft, this film emulates the drag-reducing properties of sharkskin.

Its potential benefits are substantial. Swiss International Air Lines (SWISS), having recognized the promising nature of this technology, calculated that by applying 950 square meters of this film to a Boeing 777-300ER in specific patterns aligned with the airflow, fuel consumption could be reduced by 1.1 percent. SWISS will apply the film to its full fleet of twelve Boeing 777-300ERs, and expects a total annual reduction of 4,800 tons of jet fuel and a corresponding decrease of approximately 15,200 tons of carbon dioxide emissions.

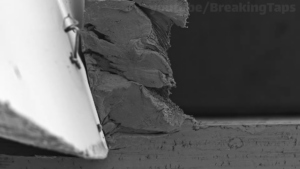

Workers applying the film to a Lufthansa aircraft. Credit: Lufthansa Cleantech Hub

" data-medium-file="https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions-1.jpg?w=400" data-large-file="https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions-1.jpg?w=800" decoding="async" loading="lazy" class="size-full wp-image-610331" src="https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions-1.jpg" alt width="800" height="449" srcset="https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions-1.jpg 1300w, https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions-1.jpg?resize=250,140 250w, https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions-1.jpg?resize=400,225 400w, https://platoaistream.com/wp-content/uploads/2023/08/sharkskin-coating-reduces-airliner-fuel-use-emissions-1.jpg?resize=800,449 800w" sizes="(max-width: 800px) 100vw, 800px">Similarly, Lufthansa has announced its plans to integrate AeroSHARK into its entire cargo freight fleet, including ten Boeing 777s. This move is estimated to save 3,700 tons of jet fuel and prevent 11,700 tons of CO2 emissions annually. It’s believed the film could be slightly more effective on cargo aircraft, which don’t have rows of passenger windows to work around.

Obviously, to go into commercial service, the AeroSHARK film has to be able to withstand the rigors of the flight environment. The film is reportedly resilient against weather extremes, UV radiation, and the considerable temperature and pressure fluctuations encountered during long-haul flights. Moreover, when applied to wing surfaces, the flow modification can even aid in generating extra lift, further increasing an aircraft’s performance.

Future work to refine the technology is ongoing, particularly with regards to expanding its application to other aircraft types. Initial calculations suggest that with further development, AeroSHARK could cut CO2 emissions by up to three percent.

The key will be whether or not the material will hold up over time and maintain its performance in real world use, where grit and grime could threaten its performance potential. If the material does work in practice, and doesn’t create undue maintenance hassles, expect it to quickly become popular with airlines across the globe. The idea of a 1 percent saving in fuel costs for the upfront price of some sticky film is one that no airline could ignore.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Automotive / EVs, Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- ChartPrime. Elevate your Trading Game with ChartPrime. Access Here.

- BlockOffsets. Modernizing Environmental Offset Ownership. Access Here.

- Source: https://hackaday.com/2023/08/23/sharkskin-coating-reduces-airliner-fuel-use-emissions/

- :has

- :is

- :not

- :where

- $UP

- 1

- 11

- 110

- 15%

- 200

- 225

- 50

- 700

- a

- Able

- above

- across

- advancements

- AeroSHARK

- Aerospace

- against

- Aid

- AIR

- aircraft

- airline

- airliner

- Airlines

- aligned

- already

- also

- always

- an

- and

- announced

- annual

- Annually

- any

- Application

- applied

- Apply

- Applying

- approximately

- ARE

- AREA

- around

- AS

- At

- aviation

- BASF

- BE

- become

- been

- believed

- benefits

- bestowed

- Better

- between

- boasts

- body

- Boeing

- but

- by

- calculated

- CAN

- carbon

- carbon dioxide

- carbon emissions

- Cargo

- cars

- Channel

- characteristics

- cleantech

- co2

- co2 emissions

- commercial

- complex

- components

- considerable

- consumption

- Corresponding

- Costs

- could

- create

- created

- creature

- credit

- Cut

- decrease

- designed

- Development

- difference

- direction

- do

- does

- Doesn’t

- Dont

- due

- during

- each

- Effective

- efficiency

- efficient

- Emissions

- enhance

- Entire

- Environment

- essentially

- estimated

- Ether (ETH)

- Even

- everything

- evolution

- expanding

- expect

- expects

- Explored

- extra

- extremes

- Feature

- Features

- figured

- Film

- First

- FLEET

- flight

- Flights

- flow

- Flowing

- fluctuations

- fluid

- For

- form

- Former

- freight

- from

- Fuel

- full

- fully

- further

- further development

- generating

- globe

- Go

- groundbreaking

- Have

- having

- help

- helps

- here

- High

- hold

- holds

- HTTPS

- idea

- if

- improve

- in

- Including

- Increase

- increasing

- industry

- initial

- innovations

- innovative

- inspired

- integrate

- interacting

- interaction

- International

- into

- involved

- IT

- ITS

- itself

- jpg

- Key

- keys

- latest

- less

- License

- like

- lines

- Lot

- lufthansa

- maintain

- maintenance

- major

- Majority

- make

- Marine

- marvel

- material

- max-width

- mechanisms

- millions

- more

- more efficient

- Moreover

- move

- Natural

- Nature

- negatively

- New

- NIH

- no

- ocean

- of

- often

- on

- ONE

- ongoing

- only

- operate

- Opportunity

- opposite

- or

- Other

- otherwise

- out

- over

- overall

- particularly

- passive

- patterns

- percent

- performance

- plans

- plato

- Plato Data Intelligence

- PlatoData

- Play

- poised

- Popular

- potential

- practice

- pressure

- prevent

- price

- Profit

- promising

- properties

- quest

- quickly

- Radiation

- real

- real world

- realm

- recognized

- reduce

- Reduced

- reduces

- reducing

- reduction

- refine

- regard

- regards

- resilient

- Respond

- result

- Revealed

- Role

- Save

- saving

- Savings

- saw

- scales

- Second

- seeking

- seen

- service

- Shark

- significant

- Skin

- small

- Social

- some

- somewhat

- Space

- specific

- square

- sticky

- Still

- structure

- substantial

- suggest

- Surface

- swimming

- Swiss

- technological

- Technologies

- Technology

- ten

- than

- that

- The

- their

- Them

- they

- this

- though?

- threaten

- three

- Through

- time

- tips

- to

- today

- tons

- too

- tool

- Total

- translate

- Translation

- treatment

- turbulence

- turbulent

- TURN

- types

- typical

- under

- understood

- unique

- unlike

- upon

- us

- use

- using

- Water

- Way..

- Weather

- What

- when

- whether

- which

- while

- whole

- Wikipedia

- will

- windows

- Wing

- with

- Work

- world

- years

- zephyrnet