The role of each function

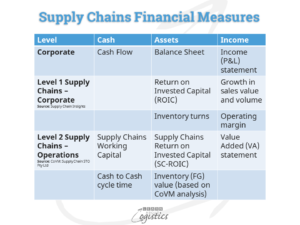

The previous blogpost identified that the Aim of a Supply Chains group is to provide ‘Competitive Availability’ of products and services. This is achieved through implementing the Objectives of the principal Supply Chains operational functions, consisting of Procurement, Operations Planning and Logistics. The driver for each function is:

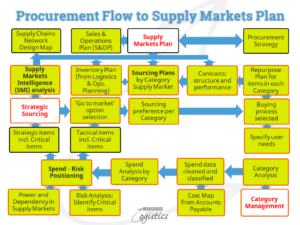

- Procurement is the building of relationships with suppliers

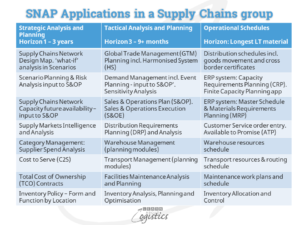

- Operations Planning (and Scheduling) it is to generate agreed plans that effectively add value to purchased materials, whether internal, at contract producers or test and pack facilities within 3PL warehouses

- Logistics is the reduction in Time through supply chains; to understand and respond to the range of external Uncertainty that might affect the organisation and reduce internal Uncertainty, caused by conflicting objectives of corporate functions

Objective of Logistics

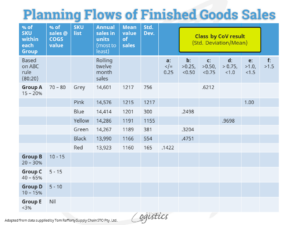

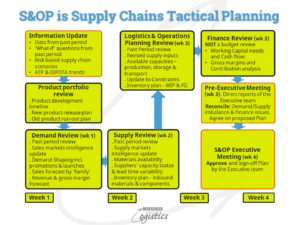

The operational activities for Logistics are governed by Operational Schedules, developed through the Sales & Operations Execution (S&OE) process for the items to be delivered and received by their due dates. While there is a potential for some item movements to be either early or late, the requirement is to achieve the Sales & Operations Plan (S&OP).

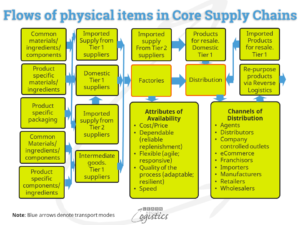

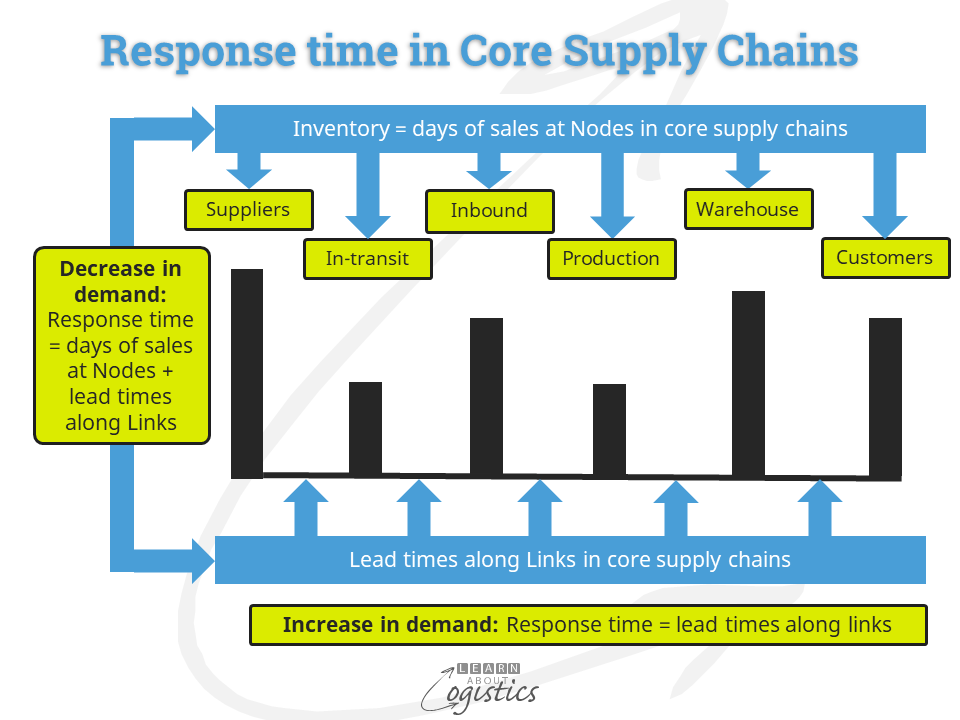

The four critical elements within supply chains are: available supply; capacity; lead times and inventory, with the last two being the responsibility of Logistics. The diagram below illustrates the linkage between lead times and inventory, as they relate to response times that occur with an increase or decrease in demand.

So, the objective is to reduce Time through the Core supply chains, but increasing the absolute speed of activities is not the objective.

Reduce Time in Supply Chains

To reduce Time through the Core supply chains requires:

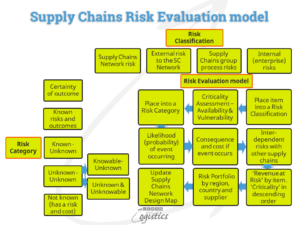

A reduction in Uncertainty. This is the term used in supply chains that identifies Risk prior to analysis. The likelihood of increased Risk of disruption for each Supply Chain will be influenced by its:

- Breadth: the number of direct Tier 1 customers and suppliers

- Depth: the number of customer and supplier Tiers in each supply chain

- Spread: the global geographical location of customers and suppliers

To enable a reduction in Uncertainty in your organisation’s Supply Chains Network, consolidate possible disruptions to those caused by:

- Complexity: built into processes, which are both internal (often management directed) and external.

- Variability: in the patterns of demand and supply

- Constraints: limitations in the Flows of items, money, transactions and information moving through an organisation’s supply chains

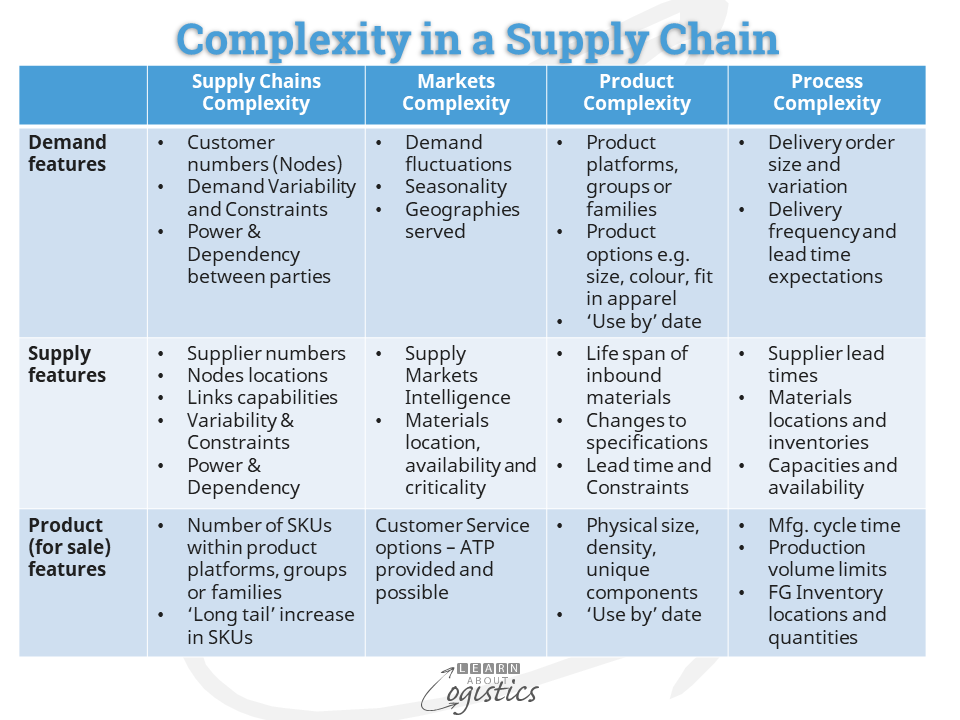

Complexity can be the most challenging to improve. The table below identifies Complexity in an organisation’s Supply Chains Network:

In addition to the factors in the table are those that occur due to executive decisions. For example:

- Mergers and Acquisitions (M&A)

- To established or sell in more countries

- Increase in product lines (SKUs) and line extensions

- Unplanned changes to demands within regions

- Regulations that change which affect supply chains

These can increase the complexity of an organisation’s supply chains, often without the provision of increased resources for the Supply Chains group.

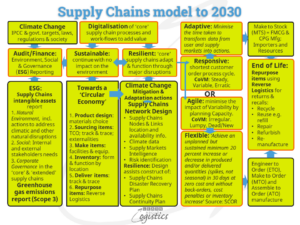

Reduce Variability. Use the Supply Chains Network Design to identify the elapsed time at each process step through the supply chains. Consider improvements that can be achieved within the next nine months. Simplify product platforms (or families) and their bills of materials (BoM)

Reduce Variability in operational processes with the TLS methodology. With complexity in supply chains a given, use the Theory of Constraints methodology to identify and if possible, eliminate bottlenecks in the Core supply chains. Then implement a Lean Six Sigma approach within the Core supply chains. A Lean methodology is used to eliminate the non value-added process steps (time variability) and Six Sigma is applied to improve execution of the processes (process variability)

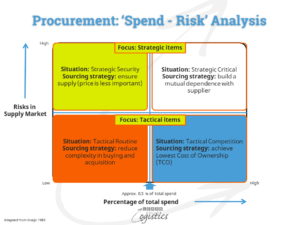

Segment customers, suppliers and inventory, to reduce buffers of inventory against Uncertainty. Work with Procurement and Operations Planning. For customers and suppliers , commercial relationship are mainly governed by the annual value of transactions; however, non-financial factors will also influence the business relationship, such as:

- type and importance of the products and/or services to a buyer or seller

- strategic importance to the business of the supplier or customer

Standardisation of materials, components and parts – does a food business require fourteen types of pepper, an electronics company 46 types of resistor or an engineering company the complete range of fasteners? Work with Design and Procurement

More responsive/agile supply chains. Work with Operations Planning to implement Postponement in the production process. This can be used as an approach to reducing the effect of uncertainty in Core supply chains. As items are held at a lower Value Added, there is a reduction in the value of inventories

A modular design process. Work with Design and Procurement whereby suppliers take increased responsibility for complete product modules

Collaboration between internal functions through the Sales & Operation Planning (S&OP) process. Work with Operations Planning to build S&OP.

Improve the timeliness of information provided to suppliers about orders, variations to orders and new product development timelines. Work with Operations Planning and Procurement

This blogpost has identified that the role of Logistics and Logisticians is broader than the efficiency and cost reduction in warehouses and transport fleets. Complex supply chains are not adaptable, so a focus is required on the reduction of Time through the supply chains, through removing and reducing Complexity. This will reduce Uncertainty, which in turn reduces the work required in Risk Analysis. These will be discussed in blogposts throughout 2024.

Please note: The next blogpost will be published on Monday February 12, 2024. Thanks for reading.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://www.learnaboutlogistics.com/the-role-of-logistics-within-the-supply-chains-group/#utm_source=rss&utm_medium=rss&utm_campaign=the-role-of-logistics-within-the-supply-chains-group

- :has

- :is

- :not

- 1

- 12

- 2024

- 3PL

- 46

- a

- About

- Absolute

- Achieve

- achieved

- acquisitions

- activities

- add

- added

- addition

- affect

- against

- agreed

- aim

- also

- an

- analysis

- and

- annual

- applied

- approach

- ARE

- AS

- At

- available

- BE

- being

- below

- between

- Bills

- both

- bottlenecks

- broader

- build

- Building

- built

- business

- but

- BUYER..

- by

- CAN

- Capacity

- caused

- chain

- chains

- challenging

- change

- Changes

- commercial

- company

- complete

- complex

- complexity

- components

- Conflicting

- Consider

- Consisting

- consolidate

- constraints

- contract

- Core

- Corporate

- Cost

- cost reduction

- critical

- customer

- Customers

- Dates

- decisions

- decrease

- delivered

- Demand

- demands

- Design

- developed

- Development

- diagram

- direct

- directed

- discussed

- Disruption

- disruptions

- does

- driver

- due

- each

- Early

- effect

- effectively

- efficiency

- either

- Electronics

- elements

- eliminate

- enable

- Engineering

- established

- Ether (ETH)

- example

- execution

- executive

- external

- facilities

- factors

- families

- February

- Flows

- Focus

- food

- For

- four

- function

- functions

- generate

- geographical

- given

- Global

- governed

- Group

- Held

- However

- HTTPS

- identified

- identifies

- identify

- if

- illustrates

- implement

- implementing

- importance

- improve

- improvements

- in

- Increase

- increased

- increasing

- influence

- influenced

- information

- internal

- into

- inventory

- IT

- items

- ITS

- Last

- Late

- lead

- LEARN

- likelihood

- limitations

- Line

- lines

- linkage

- location

- logistics

- lower

- M&A

- mainly

- management

- materials

- max-width

- Methodology

- might

- modular

- Modules

- Monday

- money

- months

- more

- most

- movements

- moving

- network

- New

- new product

- next

- nine

- note

- number

- objective

- objectives

- occur

- of

- often

- on

- OP

- operation

- operational

- Operations

- or

- orders

- organisation

- Pack

- patterns

- plan

- planning

- plans

- Platforms

- plato

- Plato Data Intelligence

- PlatoData

- possible

- potential

- previous

- Principal

- Prior

- process

- processes

- procurement

- Producers

- Product

- product development

- Production

- Products

- Products and Services

- provide

- provided

- provision

- published

- purchased

- range

- Reading

- received

- reduce

- reduces

- reducing

- reduction

- relationship

- Relationships

- removing

- require

- required

- requirement

- requires

- Resources

- Respond

- response

- responsibility

- Risk

- Role

- sales

- scheduling

- sell

- Services

- Sigma

- simplify

- SIX

- So

- some

- speed

- Step

- Steps

- such

- supplier

- suppliers

- supply

- supply chain

- Supply chains

- table

- Take

- term

- test

- than

- thanks

- that

- The

- their

- then

- theory

- There.

- These

- they

- this

- those

- Through

- throughout

- tier

- time

- timelines

- times

- TLS

- to

- Transactions

- transport

- TURN

- two

- types

- Uncertainty

- understand

- use

- used

- value

- variations

- whether

- which

- while

- will

- with

- within

- without

- Work

- Your

- zephyrnet