Manager of external risks

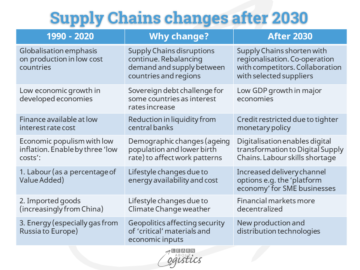

Disruption in the worlds supply chains are unlikely to reduce in number or severity, especially as the influence of climate change increases. There is an increasing need within companies to identify and understand the risks attached to the supply of materials and components, especially those from a single source supplier or country or geographical cluster.

Every raw material, part or ingredient in your company’s Bills of Materials (BOM) must be produced and delivered, irrespective of its buy cost. But when not available, an input item that costs 20 cents each to buy will suddenly have a much higher value, in terms of lost sales revenue for a business.

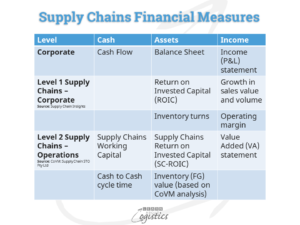

The critical role of the Supply Chains group (Procurement, Operations Planning and Logistics) is to provide Availability of finished products to satisfy customers’ demand. The lead role of Procurement is therefore to enhance the capability to provide Availability of input items, rather than just be a buyer focused on the buy price.

In the new environment, Procurement should be viewed as an organisations manager of external risks, thereby protecting the company’s gross margins. This requires Procurement to have a thorough understanding of the supply markets and climate zones they operate within.

From Uncertainty to Risk

Risks are identified and structured from uncertainties in an organisation’s Supply Chains Network, where uncertainties can also be magnified. This is due to the operations through supply chains that are non-linear (and with many ‘ifs and thens’), with outcomes that are emergent (i.e. as they happen) and cumulative, as they interact and amplify each other. In addition, the organisation’s business model will influence the uncertainties:

- Complexity: built into processes, both internal (and management directed) and external. External complexity is influenced by:

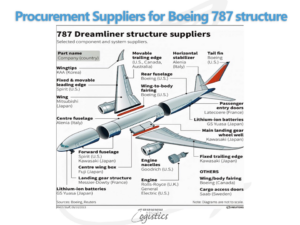

- Breadth: number of direct Tier 1 suppliers in the supply base

- Depth: number of supplier Tiers in each supply chain

- Geography: global spread of customers and suppliers

- Variability: in the patterns of demand and supply at locations in the supply chains

- Constraints: restrictions and interruptions in the flows of items, money, transactions and information as they move through an organisation’s supply chains

The highest risk to the business is if it remains in a reactive mode to events and only responds when it must. But to manage risks in your organisation’s supply chains requires an investment in understanding the supply chains and wider supply network. This is a lead role for Procurement.

The challenge to overcome is that the unit cost of an item or annual spend with a supplier does not equate to the risks associated with the purchases. The role is therefore to identify and understand the risks associated with the purchase of an item. And when the risks are better understood, negotiations about the purchase can commence.

Suppliers must be segmented in terms of the potential risks connected with the supplier and their impact on the organisation. A supply item that is identified as ‘critical’ means that a disruption in its supply could substantially impact the functioning of a business and its Procurement organisation. However, critical suppliers are likely to be a small subset of the supplier base, but they must be known.

Procurement risk model

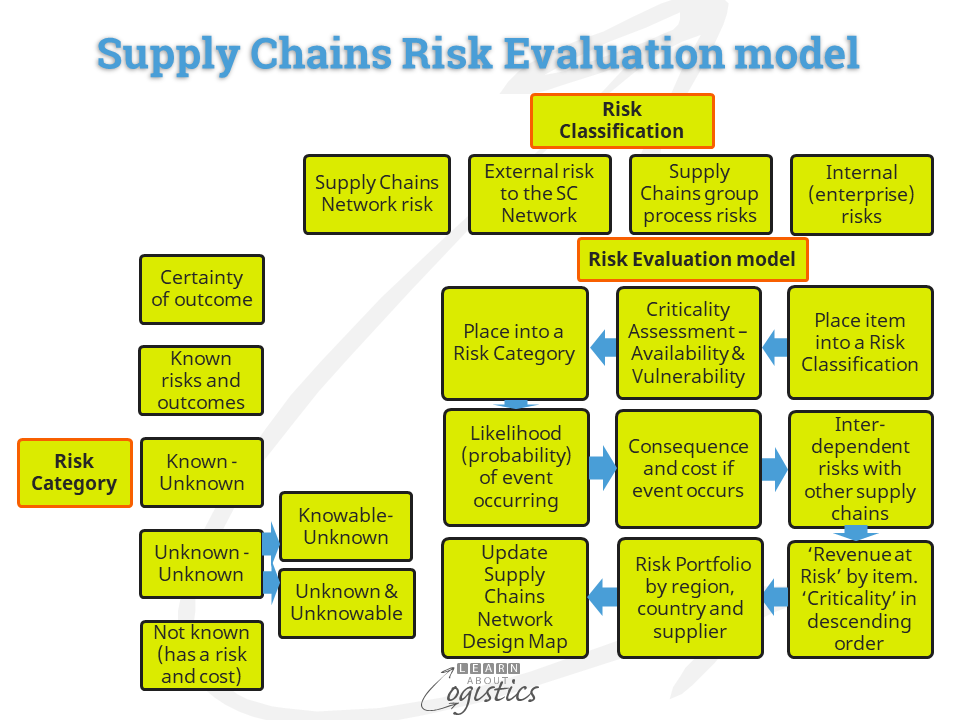

As risk management and resilience takes a higher profile, elements of the Procurement risk model must be identified. The core elements are likely to be:

- Risk Evaluation model: Enables uncertainties to be transformed to risks. See diagram below

- Supplier knowledge from the Supply Chains Network Design Map. Identify suppliers, their risks and dependencies and assess the resilience of the Supply Chains Network and vulnerability to the supply of critical materials

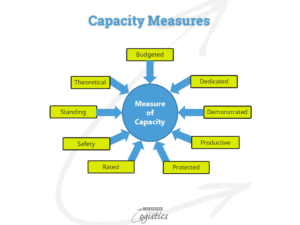

- Demand and Supply prediction from the S&OP process. Identify future capacity shortages and excessive lead time, to enable availability of sufficient inbound and outbound inventory

- ‘Revenue at Risk’ Identify and monitor the revenue value of Procurement risks that may affect future sales

- Modelling of supply chains resilience measures. Identify whether measures to improve resilience can achieve a defined set of objectives and the potential effect on Procurement activities. As negative climate change events occur, supplier businesses must increase investments in climate adaptation. This may be in preference to investments that improve operational efficiency, as the following extract illustrates:

“Areas in the western Pacific used for manufacturing products, including Korea, Japan, Taiwan, and coastal China, can expect that hurricanes sufficient to disrupt their suppliers will become two to four times more likely. Some of these disruptions may last for several months. South East China will experience extreme precipitation events twice as often by 2030” McKinsey

The recent floods in northern Italy emphasize that supply chain risks from climate change events will occur in defined geographic areas. The disruptions only become evident after the event.

- Changes in the Procurement of items due to Climate Regulations. Examples are: Scope 3 emissions liability; requirement to design for reuse, repair and refurbish; a ‘right to repair’ for products; ‘Return and Earn’ schemes for consumers

- Portfolio of approved mitigation and adaptation actions. When supply chain risks are identified, there are choices of action: transfer or share or minimize or eliminate the risk. Example of action at a manufacturer of explosives and fertilizers in Australia:

- Situation: gas is a critical input; buys gas on long term contract at prevailing world price. Currently very high, which threatens viability of the business

- Objective: negotiate new 10 year gas supply contract with price based on costs plus margin

- Action: the buyer will help fund further development of the gas field through pre-payment for the gas

- Calculate: The total cost of ownership (TCO) for item

To build the capabilities for Procurement to focus on risk and resilience requires a team that can use analytical tools and techniques. For example, risk evaluation to identify ‘revenue at risk’ and ‘should cost’ analysis. Companies will need to develop career paths that include positions in Procurement, including in senior roles.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoAiStream. Web3 Data Intelligence. Knowledge Amplified. Access Here.

- Minting the Future w Adryenn Ashley. Access Here.

- Buy and Sell Shares in PRE-IPO Companies with PREIPO®. Access Here.

- Source: https://www.learnaboutlogistics.com/the-changing-role-of-procurement-is-wider-and-deeper/#utm_source=rss&utm_medium=rss&utm_campaign=the-changing-role-of-procurement-is-wider-and-deeper

- :is

- :not

- :where

- 1

- 10

- 20

- a

- About

- Achieve

- Action

- activities

- adaptation

- addition

- affect

- After

- also

- an

- analysis

- Analytical

- and

- annual

- approved

- ARE

- areas

- AS

- associated

- At

- Australia

- availability

- available

- base

- based

- BE

- become

- Better

- Bills

- both

- build

- business

- business model

- businesses

- but

- buy

- Buys

- by

- CAN

- capabilities

- Capacity

- Career

- chain

- chains

- challenge

- change

- changing

- China

- choices

- Climate

- Climate change

- Cluster

- Companies

- Company’s

- complexity

- components

- connected

- contract

- Core

- Cost

- Costs

- could

- country

- critical

- Currently

- Customers

- deeper

- defined

- delivered

- Demand

- Design

- develop

- Development

- direct

- Disrupt

- Disruption

- disruptions

- does

- due

- e

- each

- East

- effect

- efficiency

- elements

- eliminate

- Emissions

- emphasize

- enable

- enables

- enhance

- Environment

- especially

- evaluation

- Event

- events

- evident

- example

- examples

- expect

- experience

- external

- extract

- extreme

- field

- Flows

- Focus

- focused

- following

- For

- four

- from

- functioning

- fund

- further

- further development

- future

- GAS

- geographic

- geographical

- gross

- Group

- happen

- Have

- help

- High

- higher

- highest

- However

- HTTPS

- i

- identified

- identify

- if

- illustrates

- Impact

- improve

- in

- include

- Including

- Increase

- Increases

- increasing

- influence

- influenced

- information

- input

- interact

- internal

- into

- inventory

- investment

- Investments

- irrespective

- IT

- Italy

- items

- ITS

- Japan

- just

- knowledge

- known

- korea

- Last

- lead

- LEARN

- liability

- likely

- locations

- logistics

- Long

- lost

- manage

- management

- manager

- Manufacturer

- manufacturing

- many

- map

- margins

- Markets

- material

- materials

- max-width

- May..

- means

- measures

- mitigation

- Mode

- model

- money

- Monitor

- months

- more

- move

- much

- must

- Need

- negative

- negotiations

- network

- New

- number

- objectives

- of

- often

- on

- only

- OP

- operate

- operational

- Operations

- or

- organisation

- Organisations

- Other

- outcomes

- Overcome

- ownership

- Pacific

- part

- patterns

- planning

- plato

- Plato Data Intelligence

- PlatoData

- plus

- positions

- potential

- prediction

- price

- process

- processes

- Produced

- Products

- Profile

- protecting

- provide

- purchase

- purchases

- rather

- Raw

- recent

- reduce

- regulations

- remains

- repair

- requirement

- requires

- resilience

- reuse

- revenue

- Risk

- risk management

- risks

- Role

- roles

- sales

- schemes

- scope

- see

- senior

- set

- several

- Share

- shortages

- should

- single

- small

- some

- Source

- South

- spend

- spread

- structured

- substantially

- sufficient

- suppliers

- supply

- supply chain

- Supply chains

- Taiwan

- takes

- team

- techniques

- term

- terms

- than

- that

- The

- their

- There.

- thereby

- therefore

- These

- they

- this

- those

- threatens

- Through

- tier

- time

- times

- to

- tools

- Total

- Transactions

- transfer

- transformed

- Twice

- two

- uncertainties

- Uncertainty

- understand

- understanding

- understood

- unit

- use

- used

- value

- very

- viability

- vulnerability

- Western

- when

- whether

- which

- wider

- will

- with

- within

- world

- world’s

- year

- Your

- zephyrnet

- zones