A common saying is that every disaster is caused by a chain of events, some of which can stretch back by years. Airplane disasters and near-disasters are no exception here, with all too often a small mechanical issue worsening until suddenly everything goes south. In the best case the flight crew is still able to work through the problems and figure out a way to put the aircraft down on firm soil in a single piece. This was the situation that the crew of Qantas Flight 32 (QF32) found themselves forced to deal with, as detailed in a recent article by [Kyra Dempsey], aka [Admiral Cloudberg].

When QF32 started its flight from London Heathrow in early November of 2010, everything seemed normal, but a mere four minutes after take-off from a layover at Singapore on its way to its final destination of Sydney, the #2 engine on the left wing of the Airbus A380 essentially exploded, launching shrapnel through the wing and fuselage. Although the A380 has four engines (numbered 1-4 from the left wing tip) and normally a single engine failure is not a major deal, the loss of systems that got destroyed in the explosion left the crew scrambling to diagnose the damage and implement a solution.

Fortunately, the shrapnel had not done too much damage. The flight crew was able to stabilize the aircraft and circle back to Singapore for a successful emergency landing. When the ATSB (Australian Transport Safety Bureau) examined the destroyed #2 engine, they traced the fault back to a single lubrication oil feed line for bearings inside the engine that had sprung a leak (full ATSB report). The leaking oil auto-ignited, destroying seals that let hot turbine gas in where it didn’t belong. The gas made quick work of cutting through parts of the engine, which resulted in the turbine spinning out of control until a disc shattered into many, very fast-traveling pieces of shrapnel.

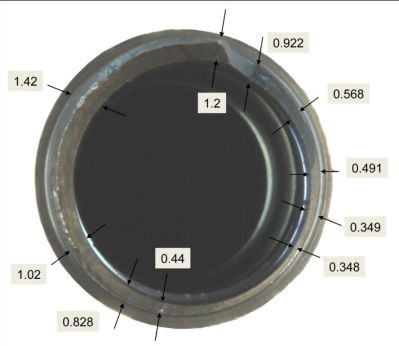

As for why the oil leak occurred? The wall thickness of the oil pipe was very irregular, with a fatigue crack coinciding with the thinnest wall section. The pressurized oil had exploited this weakness and in the process very nearly turned QF32 into a TWA-800 or Alaska Airlines Flight 261 level disaster. During the subsequent inspection of all other Rolls-Royce Trent 900 engines, a number were found to also have a similar flaw in the same piece of pipe. The pipes were quickly replaced.

[embedded content]

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://hackaday.com/2023/12/11/qantas-flight-32-when-a-few-millimeters-of-metal-invite-disaster/

- :has

- :is

- :not

- :where

- 1

- 2010

- 216

- 32

- 400

- a

- A380

- Able

- After

- Airbus

- aircraft

- Airlines

- Airplane

- aka

- All

- also

- Although

- and

- animation

- ARE

- AS

- At

- Australian

- back

- BEST

- Bureau

- but

- by

- CAN

- case

- caused

- chain

- Circle

- Common

- content

- control

- crack

- crew

- cutting

- damage

- deal

- destination

- destroyed

- detailed

- disaster

- disasters

- done

- down

- during

- Early

- embedded

- emergency

- Engine

- Engines

- essentially

- Ether (ETH)

- events

- Every

- everything

- exception

- exploited

- explosion

- faa

- Failure

- fatigue

- few

- Figure

- final

- Firm

- flaw

- flight

- For

- found

- four

- from

- GAS

- Goes

- got

- had

- Have

- here

- HOT

- HTTPS

- implement

- in

- inside

- into

- invite

- IP

- issue

- IT

- ITS

- jpg

- kyra

- landing

- launching

- leak

- left

- let

- Level

- Line

- London

- loss

- made

- major

- many

- max-width

- measurements

- mechanical

- medium

- mere

- metal

- minutes

- much

- nearly

- no

- normal

- normally

- November

- number

- numbered

- occurred

- of

- often

- Oil

- on

- or

- Other

- out

- parts

- piece

- pieces

- pipe

- pipes

- plato

- Plato Data Intelligence

- PlatoData

- problems

- process

- put

- Quick

- quickly

- replaced

- resulted

- Rolls-Royce

- Safety

- same

- saying

- Section

- seemed

- Sequence

- similar

- Singapore

- single

- situation

- small

- soil

- solution

- some

- Source

- South

- stabilize

- started

- Still

- subsequent

- successful

- sydney

- Systems

- that

- The

- themselves

- they

- this

- Through

- tip

- to

- too

- transport

- turbine

- Turned

- until

- very

- Wall

- was

- Way..

- weakness

- were

- when

- which

- why

- Wikipedia

- Wing

- with

- Work

- years

- youtube

- zephyrnet