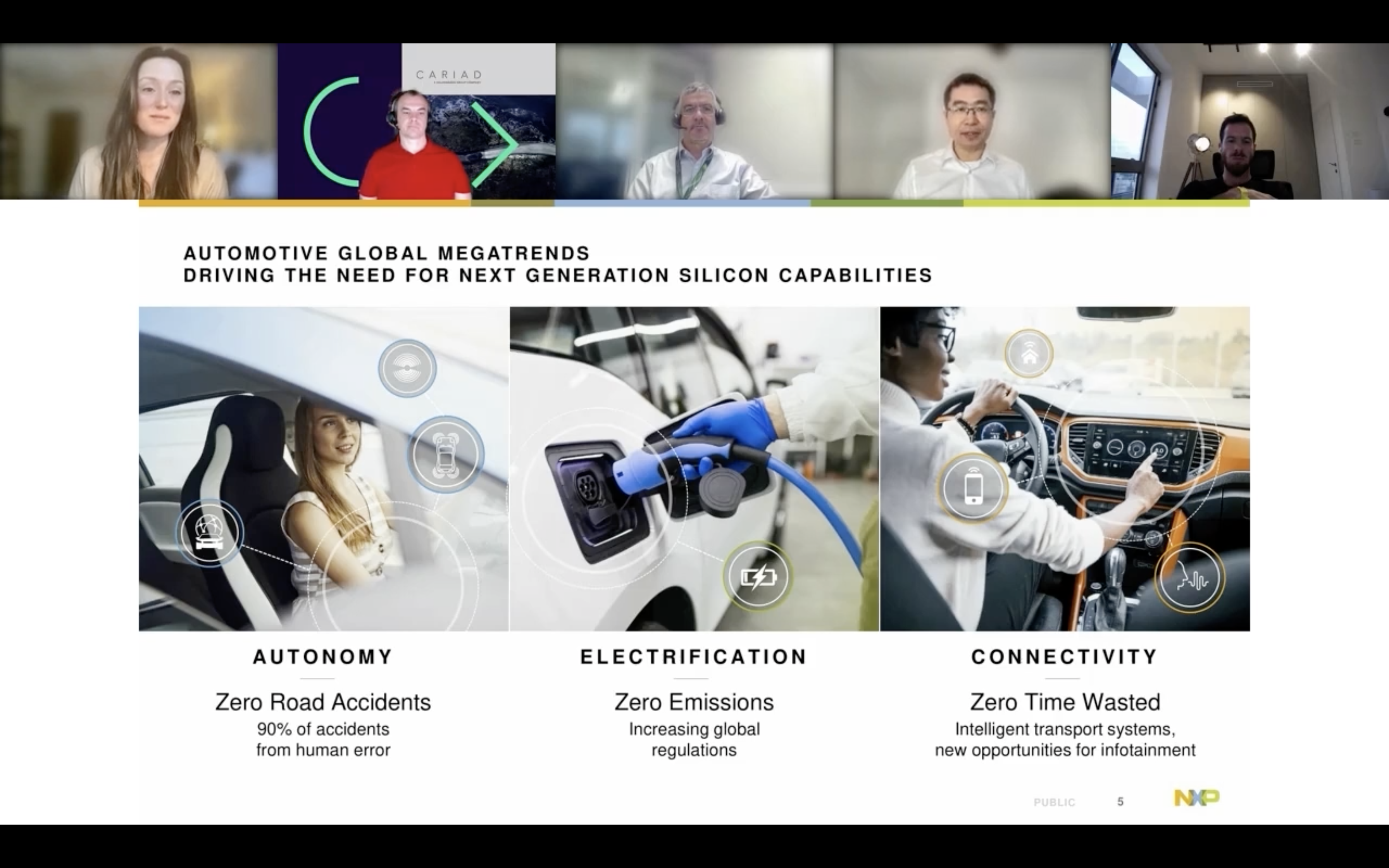

The automotive industry is on the brink of a revolutionary transformation, where predictive maintenance and monitoring are taking center stage. In a recent webinar panel session, industry experts delved into the challenges, current approaches, and future innovations surrounding the guarantee and extension of mission profiles.

proteanTecs hosted that webinar with the following experts as panelists:

Heinz Wagensonner, Sr. SoC Designer, CARIAD (software division of Volkswagen Group)

Jens Rosenbusch, Sr. Principal Engineer, SoC Safety Architecture, Infineon Technologies,

Xiankun “Robert” Jin, Automotive SoC Safety Architect, NXP Semiconductors, and

Gal Carmel, Executive VP, GM, Automotive, proteanTecs. Ellen Carey, Chief External Affairs Officer, Circulor, moderated the panel session.

The key themes that emerged were the increasing reliance on artificial intelligence (AI), the importance of real-time monitoring, and the need for a paradigm shift in industry thinking. The following are the salient points that came out of that panel session. You can access that entire panel session on-demand from here.

Current Challenges

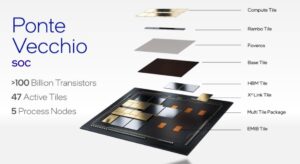

The conversation began by acknowledging the challenges faced by the automotive sector. For instance, the introduction of a Central Gateway controller connected to the cloud for extended periods poses challenges for reliability and safety. Traditionally, managing uncertainties involved building margins into design, fabrication, and testing processes. However, this approach may become unsustainable in the future.

Current Approaches

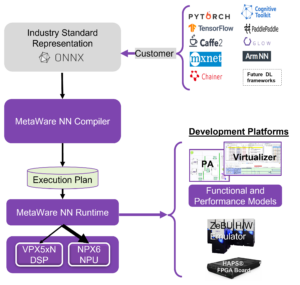

To address these challenges, the industry is shifting towards a more proactive and predictive maintenance approach. Rather than relying solely on built-in margins, the emphasis is on implementing health monitors or sensors that continually assess the device’s status. This data is aggregated and analyzed, potentially through machine learning, providing insights that were previously inaccessible. This newfound understanding enables decisions such as swapping devices before imminent failure, a concept known as predictive maintenance.

Collaboration and Standardization

The transition to predictive maintenance is not a journey undertaken by individual companies but requires collaborative efforts within the automotive industry. One significant initiative mentioned during the panel session is the creation of a framework for automotive predictive maintenance. A technical report, TR 9839, was published during the past summer, paving the way for the Third Edition of ISO 26262 standard. This collaborative approach involves stakeholders, including semiconductor vendors, original equipment manufacturers (OEMs), and regulatory bodies.

The Role of AI in Predictive Maintenance

The integration of AI emerged as a crucial factor in revolutionizing predictive maintenance. AI’s ability to analyze vast datasets and identify patterns that may elude human observers makes it a valuable tool for predicting failures. Whether optimizing production processes or analyzing failures in the field, AI plays a pivotal role in enhancing efficiency and accuracy.

AI is not just about finding known issues but uncovering latent defects or anomalies that may lead to failures. The application of AI in the analysis of sensor data from millions of vehicles in a fleet opens up possibilities for early detection of potential failures. However, the discussion also highlighted the importance of standardizing AI applications to ensure accuracy and reliability.

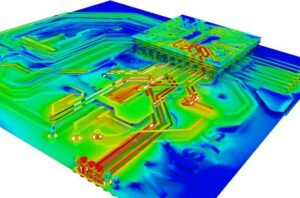

On-Chip Monitoring for Real-Time Insights

A critical aspect of transforming automotive maintenance is the adoption of on-chip monitoring. The traditional process of failure analysis, involving sending faulty components back for analysis, was deemed slow and inefficient. On-chip monitoring, if implemented effectively, can provide real-time insights into the behavior of silicon while the vehicle is in operation.

The Future Landscape

As the automotive industry moves towards autonomy and increased connectivity, the need for a flexible and adaptive approach to maintenance becomes paramount. The speakers emphasized a change in thinking, where a cross-platform, data-driven approach is embraced. This involves creating a common language, pooling insights, and utilizing a combination of hardware mechanisms and software analytics to drive proactive maintenance.

Summary

The panel session highlighted the industry’s dynamic shift from reactive to proactive maintenance strategies. The integration of AI and on-chip monitoring represents a leap forward in enhancing reliability, reducing costs, and improving overall product quality. Collaboration among industry stakeholders, standardization efforts, and a change in thinking towards a vertical approach will be key in shaping the future of automotive maintenance. As the industry navigates this transformative journey, the focus remains on leveraging technology to ensure vehicles not only meet but exceed reliability and safety standards.

You can listen to the entire panel session here.

Also Read:

Building Reliability into Advanced Automotive Electronics

Unlocking the Power of Data: Enabling a Safer Future for Automotive Systems

proteanTecs On-Chip Monitoring and Deep Data Analytics System

Share this post via:- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://semiwiki.com/ip/339946-fail-safe-electronics-for-automotive/

- :is

- :not

- :where

- $UP

- a

- ability

- About

- access

- accuracy

- adaptive

- address

- Adoption

- advanced

- Affairs

- AI

- also

- among

- an

- analysis

- analytics

- analyze

- analyzed

- analyzing

- and

- Application

- applications

- approach

- approaches

- architecture

- ARE

- artificial

- artificial intelligence

- Artificial intelligence (AI)

- AS

- aspect

- assess

- automotive

- automotive industry

- Autonomy

- back

- BE

- become

- becomes

- before

- began

- behavior

- bodies

- brink

- Building

- built-in

- but

- by

- came

- CAN

- Center

- center stage

- central

- challenges

- change

- chief

- Cloud

- collaboration

- collaborative

- combination

- Common

- Companies

- components

- concept

- connected

- Connectivity

- continually

- controller

- Conversation

- Costs

- Creating

- creation

- critical

- critical aspect

- cross-platform

- crucial

- Current

- data

- Data Analytics

- data-driven

- datasets

- decisions

- deemed

- deep

- Design

- Designer

- Detection

- Devices

- discussion

- Division

- drive

- driving

- during

- dynamic

- Early

- edition

- effectively

- efficiency

- efforts

- Electronics

- embraced

- emerged

- emphasis

- emphasized

- enables

- enabling

- engineer

- enhancing

- ensure

- Entire

- equipment

- exceed

- executive

- experts

- extended

- extension

- external

- faced

- factor

- Failure

- failures

- faulty

- field

- finding

- FLEET

- flexible

- Focus

- following

- For

- Forward

- Framework

- from

- future

- gateway

- generation

- GM

- Group

- guarantee

- Hardware

- Health

- here

- Highlighted

- hosted

- However

- HTTPS

- human

- identify

- if

- implemented

- implementing

- importance

- improving

- in

- inaccessible

- Including

- increased

- increasing

- individual

- industry

- industry experts

- industry’s

- inefficient

- Infineon

- Initiative

- innovations

- insights

- instance

- integration

- Intelligence

- into

- Introduction

- involved

- involves

- involving

- ISO

- issues

- IT

- journey

- just

- Key

- known

- language

- lead

- Leap

- learning

- leveraging

- machine

- machine learning

- maintenance

- MAKES

- managing

- Manufacturers

- margins

- max-width

- May..

- mechanisms

- Meet

- mentioned

- millions

- Mission

- monitoring

- monitors

- more

- moves

- navigates

- Need

- next

- nxp semiconductors

- observers

- of

- Officer

- on

- On-Demand

- ONE

- only

- opens

- operation

- optimizing

- or

- original

- out

- overall

- panel

- paradigm

- Paramount

- past

- patterns

- Paving

- periods

- pivotal

- plato

- Plato Data Intelligence

- PlatoData

- plays

- points

- poses

- possibilities

- Post

- potential

- potentially

- power

- predicting

- predictive

- previously

- Principal

- Proactive

- process

- processes

- Product

- Product Quality

- Production

- Profiles

- provide

- providing

- published

- quality

- rather

- Read

- real-time

- recent

- reducing

- regulatory

- reliability

- reliance

- relying

- remains

- report

- represents

- requires

- Revolution

- revolutionary

- Revolutionizing

- Role

- safer

- Safety

- sector

- semiconductor

- Semiconductors

- sending

- sensor

- sensors

- session

- shaping

- shift

- SHIFTING

- significant

- Silicon

- slow

- Software

- solely

- speakers

- Stage

- stakeholders

- standard

- standardization

- standardizing

- standards

- Status

- strategies

- such

- summer

- Surrounding

- swapping

- taking

- Technical

- Technologies

- Technology

- Testing

- than

- that

- The

- The Future

- themes

- These

- Thinking

- Third

- this

- Through

- to

- tool

- towards

- traditional

- traditionally

- Transformation

- transformative

- transforming

- transition

- uncertainties

- understanding

- unsustainable

- Utilizing

- Valuable

- Vast

- vehicle

- Vehicles

- vendors

- vertical

- via

- volkswagen

- Volkswagen Group

- vp

- was

- Way..

- webinar

- were

- whether

- while

- will

- with

- within

- you

- zephyrnet