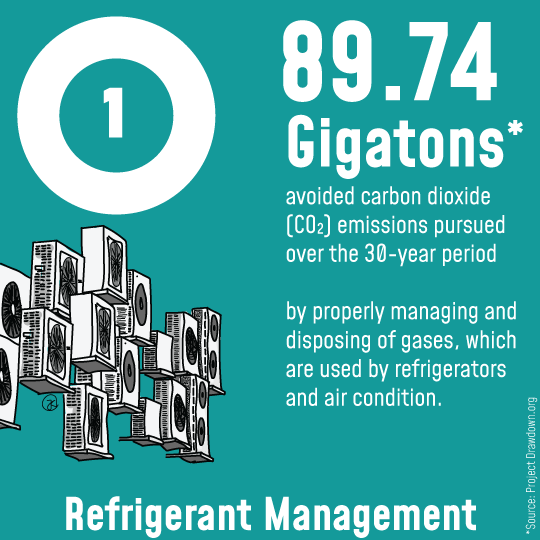

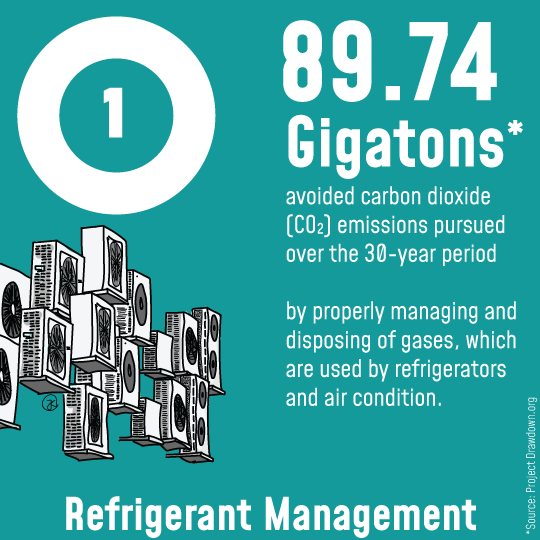

Refrigerants are vital to modern comfort and convenience — found in air conditioners, chillers, refrigerators and heat pumps (which in 2022 overtook the sale of gas furnaces in the U.S.)

Their primary function: absorb and release heat by phase changing between a liquid and a gas.

Pretty cool stuff except that most refrigerants in use happen to be super-potent greenhouse gasses. And as the planet warms and the need for cooling increases, so does the use of these chemicals — creating a vicious cycle of global warming.

Here are the top three reasons to care about refrigerants:

- The primary type of refrigerants used today are a class of chemicals called hydrofluorocarbons (HFCs), the fastest growing greenhouse gasses in the world.

- HFCs are hundreds to thousands of times more potent at trapping heat in our atmosphere than carbon dioxide.

- The solutions to this problem are immediately actionable, cost effective and impactful (more on this below)

A brief history

I think the refrigerant dilemma is best understood in the context of how we got into the current situation.

1930s — Chlorofluorocarbons (CFCs) were invented and quickly became the standard refrigerants used in air conditioners. Prior to this point, early refrigeration systems used natural refrigerants such as ammonia, which is making a comeback.

1987 — CFCs are globally recognized as damaging the ozone layer and are phased out of production through the passing of the Montreal Protocol, widely considered to be one of the most successful global treaties of all time.

2010 — The U.S. Environmental Protection Agency bans the production and import of CFC-based refrigerants in the U.S. Air conditioning manufacturers switch to R-410A, a blend of synthetic fluorinated gasses (F-gasses) called hydrofluorocarbons (HFCs).

2016 — The Kigali Amendment to the Montreal Protocol sets the stage for a global phase-down of high-potency HFCs such as R-410A due to their high global warming potential.

The state of policy today

That brings us to the present. The good news is that there are global, national and some state-level regulations in place for phasing out HFCs — and best practices and technology solutions are emerging to get that job done.

State Regulations

As is the case with other climate policies, progressive states are leading the way faster than the U.S. federal government and global organizations such as the United Nations.

- California created its Refrigerant Management Program (RMP) in 2009. It requires refrigerant leak inspections, as well as repairs and reports on refrigeration systems such as commercial cold food storage equipment that contains more than 50 pounds of high global warming potential refrigerant. In 2020, California adopted first-in-the-nation HFC prohibitions, including global warming potential (GWP) limits for new refrigeration and AC equipment.

- New York state has a smattering of regulations related to refrigerants: 6 CRR-NY 361-1.5 requires proper end-of-life management, while NYSDEC Part 494 regulates the use of HFCs in new equipment. The Office of General Services has a great website about refrigerant management.

- Washington state started its HFC regulations in 2019 and has been steadily ratcheting up requirements for reporting, repairs and phaseouts.

For the sake of brevity I will stop here, but other states including Vermont, Maryland, Connecticut and Delaware have passed or are working on passing HFC regulations — with many more states likely to follow.

Federal Policies

The U.S. federal government’s work on this issue is covered by The American Innovation and Manufacturing (AIM) Act. This legislation authorized the EPA in 2020 to develop regulations for the phasedown of HFCs. The overall goal is a 85 percent reduction of HFCs by 2036. The policy mechanisms used include establishing allowances for the production and consumption of HFCs, providing sector-specific GWP limits and writing HFC refrigerant management practices. Each specific policy is in various stages of development, with the refrigerant management practices expected to be shared this fall.

Global Treaties

The global work on phasing down HFCs is also in the spotlight. Last week, a working group for the Montreal Protocol held its regular mid-year meeting to set the agenda for a Meeting of the Parties later this year. Life-cycle refrigerant management was heavily featured, setting the stage for what could be significant decisions at the next gathering.

The United Nations Environment Programme (UNEP) also announced early this year that sustainable cooling will be a focus for the COP28 Climate Change Conference in the United Arab Emirates. UNEP and the COP28 presidency are working on a Global Cooling Pledge aimed at accelerating access and implementation of sustainable cooling solutions.

Why are you waiting?

Against this backdrop of policy evolution, there are actions building and facilities managers can take today to mitigate the greenhouse gas emissions of refrigerants. The solutions fall into two categories:

- Life-cycle refrigerant management (LRM) is a holistic, circular approach to the process of identifying, tracking and managing refrigerants throughout their life cycle. Refrigerant users can get started with LRM by completing an inventory of their total refrigerants in use, committing to prevent and repair leaks, and purchasing only reclaimed HFC refrigerants to service equipment.

- Alternative refrigerants that have a low or no global warming potential include hydrocarbons (propane or isobutane), ammonia (NH3) and carbon dioxide (CO2). Interestingly these substances were used as refrigerants before the 1930s when F-gasses were introduced. The innovations being developed are less in the refrigerants themselves and more in the technology that enables these refrigerants to perform to modern standards of safety and allowing us to leverage their climate benefits. For some end-uses such as commercial refrigeration, these solutions are already readily available and cost effective. For other sectors such as air conditioning and heat pumps, there is limited availability, but significant efforts are being made to bring these products to market in the U.S. more widely.

To-do list

The Montreal Protocol and the subsequent phasing out of ozone-depleting substances is a bonafide environmental success story. We can repeat that win with the next phase of refrigerant management.

Below are some links to help your company take action on refrigerants now.

How many action items can you check off? Please forward, repost and reply to this piece with what you have gotten done. Let’s celebrate our successes.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Automotive / EVs, Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- BlockOffsets. Modernizing Environmental Offset Ownership. Access Here.

- Source: https://www.greenbiz.com/article/cheat-sheet-managing-refrigerants

- :has

- :is

- $UP

- 15%

- 2019

- 2020

- 2022

- 50

- a

- About

- AC

- accelerating

- access

- Act

- Action

- actions

- adopted

- agency

- agenda

- aim

- aimed

- AIR

- Air Conditioning

- All

- Allowing

- already

- also

- American

- Ammonia

- an

- analysis

- and

- Arab

- ARE

- article

- AS

- At

- Atmosphere

- authorized

- availability

- backdrop

- Bans

- BE

- became

- been

- before

- being

- below

- benefits

- BEST

- best practices

- between

- Blend

- bring

- Brings

- Building

- but

- by

- CA

- california

- called

- CAN

- Can Get

- carbon

- carbon dioxide

- care

- case

- categories

- celebrate

- Center

- change

- changing

- check

- chemicals

- class

- clean energy

- click

- Climate

- Climate change

- co2

- cold

- Comeback

- comfort

- commercial

- committing

- company

- completing

- Conference

- considered

- consumption

- contains

- context

- convenience

- Cool

- cop28

- Cost

- could

- covered

- created

- Creating

- Current

- cycle

- damaging

- data

- decisions

- Default

- Delaware

- develop

- developed

- Development

- does

- done

- down

- due

- each

- Early

- Effective

- efforts

- emerging

- emirates

- Emissions

- enables

- energy

- Environment

- environmental

- Environmental Protection Agency

- EPA

- equipment

- establishing

- evolution

- Except

- expected

- facilities

- Fall

- faster

- featured

- Federal

- Federal government

- Focus

- follow

- food

- For

- Forward

- found

- function

- GAS

- gathering

- General

- get

- Global

- global warming

- Globally

- goal

- good

- Government

- great

- greenhouse gas

- Greenhouse gas emissions

- Group

- Growing

- happen

- Have

- heavily

- Held

- help

- here

- HFC

- High

- holistic

- How

- HTTPS

- i

- identifying

- IEA

- immediately

- impactful

- implementation

- import

- in

- include

- Including

- Increases

- Innovation

- innovations

- into

- introduced

- Invented

- inventory

- issue

- IT

- items

- ITS

- Job

- Last

- later

- layer

- leading

- leak

- Leaks

- Legislation

- less

- Leverage

- Life

- life-cycle

- likely

- Limited

- limits

- links

- Liquid

- Low

- made

- Making

- management

- Managers

- managing

- Manufacturers

- manufacturing

- many

- Market

- Maryland

- mechanisms

- meeting

- Mitigate

- Modern

- Montreal

- more

- most

- move

- National

- Nations

- Natural

- Need

- New

- news

- Newsletter

- next

- no

- node

- now

- NY

- of

- off

- Office

- on

- only

- or

- organizations

- Other

- our

- out

- overall

- part

- parties

- passed

- Passing

- percent

- perform

- phase

- Phased

- piece

- Place

- planet

- plato

- Plato Data Intelligence

- PlatoData

- please

- Point

- policies

- policy

- potential

- pounds

- practices

- present

- presentation

- prevent

- primary

- Prior

- Problem

- process

- Production

- Products

- Program

- programme

- progressive

- proper

- protection

- protocol

- providing

- pumps

- purchasing

- quickly

- reasons

- recognized

- reduction

- regular

- regulations

- related

- release

- repair

- repeat

- reply

- Reporting

- Reports

- Requirements

- requires

- s

- Safety

- sake

- sale

- SC

- sector-specific

- Sectors

- service

- Services

- set

- Sets

- setting

- shared

- sheet

- sign

- significant

- situation

- So

- Solutions

- some

- specific

- Spotlight

- Stage

- stages

- standard

- standards

- started

- State

- States

- Stop

- storage

- Story

- subsequent

- success

- success story

- successful

- such

- sustainable

- Switch

- synthetic

- Systems

- Take

- Technology

- than

- that

- The

- the world

- their

- themselves

- There.

- These

- think

- this

- this year

- thousands

- three

- Through

- throughout

- times

- to

- today

- top

- Total

- Tracking

- transition

- trapping

- two

- type

- u.s.

- UN

- understood

- United

- United Arab Emirates

- united nations

- us

- use

- used

- users

- various

- vital

- Waiting

- want

- Warms

- was

- Way..

- we

- week

- WELL

- were

- What

- when

- which

- while

- widely

- will

- win

- with

- Work

- working

- Working Group

- world

- writing

- year

- york

- you

- Your

- zephyrnet