<!–

–>

Personalised medical devices are uniquely suited to the patient, improving fit, comfort, and outcomes while reducing the risk of complications.

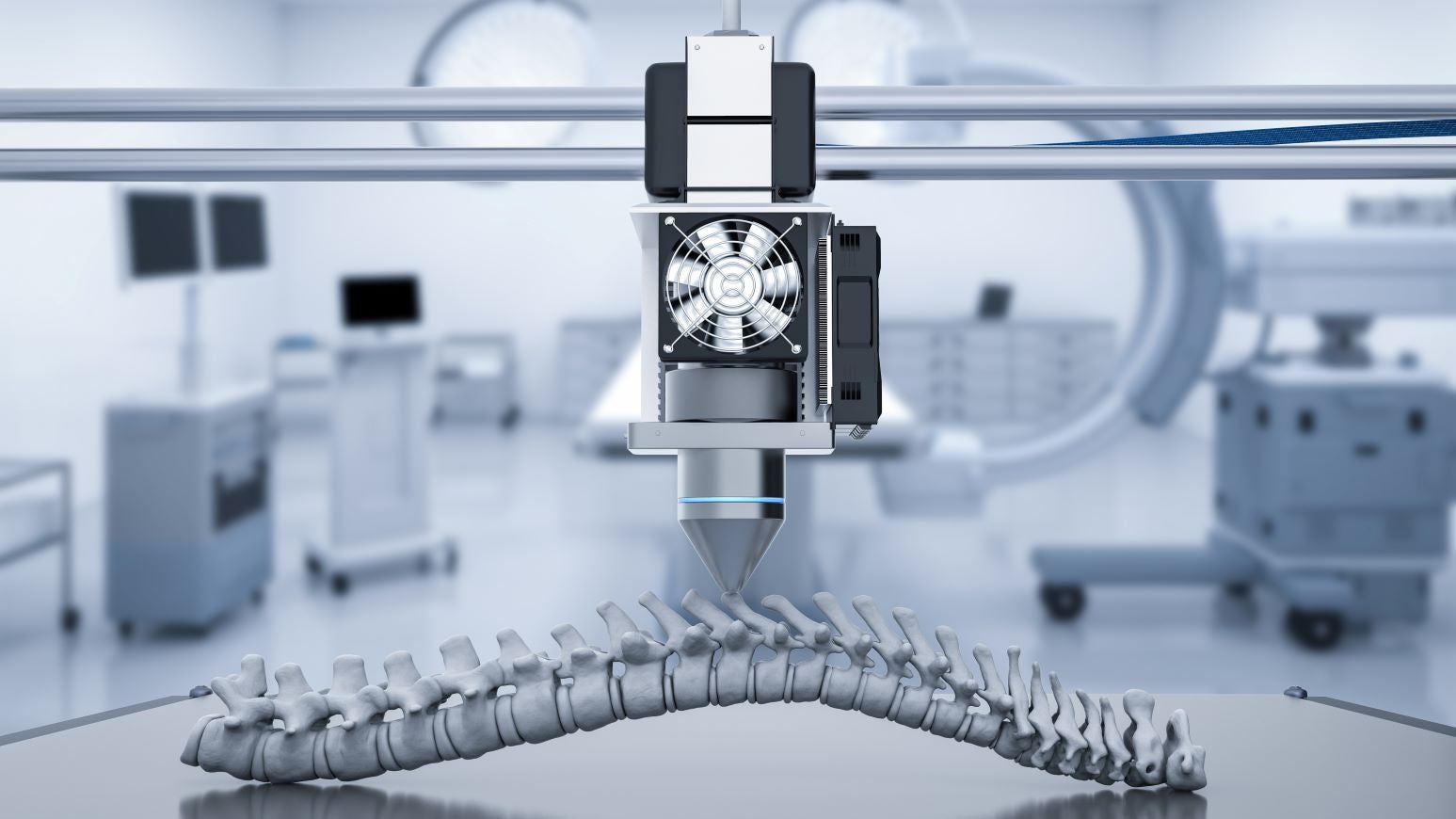

3D printing, or additive manufacturing, is the process of joining materials layer by layer to construct an object from three-dimensional data. This makes it possible to construct devices with intricate structures, internal cavities, and unconventional geometries that are very difficult or impossible to construct using traditional manufacturing. Devices are typically produced in small batches, and designs can be iteratively altered to reduce components, weight, and cost to create lightweight, compact medical devices with internal functionality.

3D printing revenue in the medical devices space has been steadily increasing since 2018, with numerous applications in orthopaedic, dental, interbody, surgical, and personalised devices. 3D printing can be used to create custom prosthetics and implants to meet the individual needs of a patient, improving functionality and patient comfort. 3D-printed surgical guides can also aid surgeons performing joint replacement, spinal, and other complex surgeries, leading to improved accuracy and precision during procedures, increased success rates, and reduced recovery times.

GlobalData, a leading data and analytics company, forecasts that customisation, lower production costs, and quick turnarounds will drive growth within the medical 3D printing market from just over $2 billion in sales in 2022, to $4 billion in 2026 at a compound annual growth rate (CAGR) of 21%. More information on the macroeconomic, technology, and regulatory trends shaping the 3D printing medical devices market is available in GlobalData’s latest report, 3D Printing in Medical Devices – Thematic Intelligence.

3D printing complements traditional manufacturing by offering new opportunities for personification and small-batch production of complicated parts. It offers great design freedom and has little to no additional cost for increasing the complexity of a design, making it a perfect tool for rapid prototyping. This can help to accelerate the development process for new devices at a fraction of the time and cost.

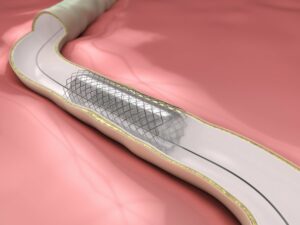

With more research, 3D printing could also lead to printed ‘smart materials’, with geometries that are nearly impossible to produce using other methods. Smart materials respond to stimuli in their environment such as heat, moisture, or sound, and are promising for medical applications as they can enhance current devices with new properties and improved performance. Prosthetic limbs with built-in sensitivity, self-expanding stents, self-healing joint replacements, and drug delivery devices that respond to infection are just some of the ‘smart’ devices currently being researched. While these devices are still far from commercial production, their research and design can benefit from the customisable, small-batch, low-cost, and design freedoms that 3D printing allows.

As investments in 3D printing continue to grow across all industries, the number of companies with 3D printing software, hardware, materials, and services will increase. This will accelerate the decentralisation of medical device production and improve device accessibility and distribution. As 3D printing continues to evolve, GlobalData expects to see even more innovative and exciting medical applications for this technology.

<!– GPT AdSlot 3 for Ad unit 'Verdict/Verdict_In_Article' ### Size: [[670,220]] —

!– End AdSlot 3 –>

- SEO Powered Content & PR Distribution. Get Amplified Today.

- Platoblockchain. Web3 Metaverse Intelligence. Knowledge Amplified. Access Here.

- Source: https://www.medicaldevice-network.com/comment/3d-printing-low-cost-personalised-medical-devices/

- 2018

- 2022

- 3d

- 3D Printing

- a

- accelerate

- accessibility

- accuracy

- across

- Ad

- Additional

- additive manufacturing

- Aid

- All

- allows

- analytics

- and

- annual

- applications

- available

- being

- benefit

- Billion

- built-in

- CAGR

- cavities

- comfort

- commercial

- Companies

- company

- complex

- complexity

- complicated

- components

- Compound

- construct

- continue

- continues

- Cost

- Costs

- could

- create

- credit

- Current

- Currently

- custom

- customisable

- data

- decentralisation

- delivery

- Design

- designs

- Development

- device

- Devices

- difficult

- distribution

- drive

- drug

- during

- Environment

- Even

- evolve

- exciting

- expects

- fit

- fraction

- Freedom

- from

- functionality

- future

- GlobalData

- great

- Grow

- Growth

- Guides

- Hardware

- help

- HTTPS

- impossible

- improve

- improved

- improving

- in

- Increase

- increased

- increasing

- individual

- industries

- infection

- information

- innovative

- Intelligence

- internal

- Investments

- IT

- joining

- joint

- latest

- layer

- lead

- leading

- lightweight

- little

- Macroeconomic

- MAKES

- Making

- manufacturing

- Market

- materials

- medical

- Medical Applications

- medical device

- medical devices

- Meet

- methods

- more

- nearly

- needs

- New

- number

- numerous

- object

- offering

- Offers

- opportunities

- Other

- parts

- patient

- perfect

- performance

- performing

- plato

- Plato Data Intelligence

- PlatoData

- possible

- Precision

- procedures

- process

- produce

- Produced

- Production

- promising

- properties

- Prosthetics

- prototyping

- Quick

- rapid

- Rate

- Rates

- recovery

- reduce

- Reduced

- reducing

- regulatory

- report

- research

- Respond

- revenue

- Risk

- sales

- Sensitivity

- Services

- shaping

- Share

- shutterstock

- since

- Size

- small

- smart

- Software

- some

- Sound

- Space

- Still

- success

- such

- surgical

- Technology

- The

- The Future

- their

- thematic

- three-dimensional

- time

- times

- to

- tool

- traditional

- Trends

- turnarounds

- typically

- unconventional

- unit

- weight

- while

- will

- within

- zephyrnet