From where I am sitting, the earth is flat. The floor that runs the length of the unit my hackerspace sits in is flat, the concrete apron behind it on which we test our Hacky Racers is flat, and a few undulations in terrain notwithstanding, it remains flat as I walk up the road towards Stony Stratford.

Of course, Hackaday hasn’t lost its mind and joined the conspiracy theorists, the earth is definitely spherical as has been known and proved multiple times since antiquity. But my trivial observation made in a damp part of Buckinghamshire still holds; that for a given value of flat which disregards a few lumps and bumps in the ground, my corner of the English city of Milton Keynes is pretty flat. Which leads from a philosophical discussion to an engineering one, if I can reasonably describe a city-sized area on an Earth-sized sphere as flat, how flat does a surface have to be to be considered flat? And from that stems a fascinating story of the evolution of precision machining.

Precision Starts With Something Flat

The history of machine tools stretches back into antiquity, in that simple lathes have been found in the archeological record of several regions of the world. There’s an industry which just about survives using rudimentary lathes pretty close to where I grew up, the chair bodgers in the English Chiltern hills use temporary pole lathes which wrap a rope around the part to be turned and balance it against the springiness of a tree branch to turn traditional wooden chair legs.

But these machines and their more refined descendants, while very good at producing the turned items they do, are not precision tools. The dimensions of the bodger’s chair leg depends on his eye and skill rather than the machine itself, because it lacks the flat bed of a modern machinist’s lathe as a baseline for its tooling. Like the city of Milton Keynes mentioned above, it’s easy to make something that looks pretty flat, but it remains hard to make something which is flat enough to use as a reference from which to machine other things. The method for making a truly flat surface without another to compare it against is thus one of the most significant innovations in the history of engineering, and definitely deserves a look.

Flatness Without Precision Tooling

The problem facing anyone tackling the manufacture of a flat surface is that by using a tool on a piece of material, be it one stone rubbed against another, a plane on a piece of wood, or a file on a piece of metal, the work piece will reflect the imperfections in the tool and in the technique.

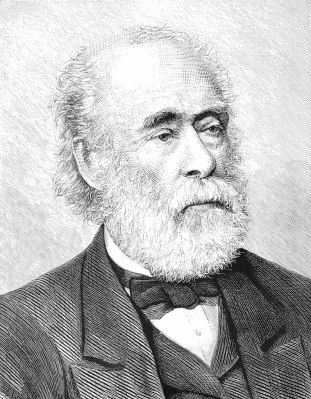

Thus it’s not too difficult to make something that looks fairly flat, but the result will not be really flat. Rub two pieces of stone together and they will become smooth for example, but it’s likely that they will tend towards one becoming concave and the other convex. The problem of making a truly flat surface in this way was solved in the 1830s by Joseph Whitworth, he of the Whitworth standard threads, who instead of testing two surfaces against each other, instead used three.

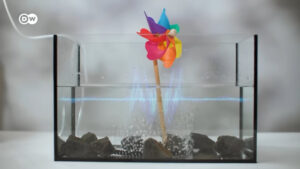

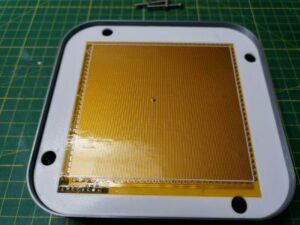

The idea was that having a set of three plates and testing them in pairs against each other in turn, he could eliminate the errors in one affecting the other. By coating the surfaces with engineer’s blue, a dye, he could lap one surface against another leaving the areas in which there was a gap between them as blue. He could thus machine the layers down where the blue dye had been worn away and repeat the process against each of the other plates in turn, until he was left with three perfectly flat surfaces that could be used as standards in his machine tools. It’s by necessity a slow process as you can see in this video, but its beauty is that it can be done without precision tooling.

There probably aren’t many inventions that could be claimed as somewhere at the basis of so many others as can Whitworth’s flat surfaces without being more widely known in their own right. But the precision his technique afforded to every subsequent piece of engineering lives on with us today, and its elegance is in its simplicity. In every engineer lurks a metrologist, and it’s in things like Whitworth’s three plate method that mine finds fulfillment.

Surface plate header image: Rrudzik, CC0.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://hackaday.com/2023/12/06/when-nearly-flat-isnt-really-flat/

- :has

- :is

- :not

- :where

- $UP

- 1

- 120

- 250

- 300

- 32

- 400

- a

- About

- above

- Action

- affecting

- afforded

- against

- am

- an

- and

- Another

- anyone

- ARE

- AREA

- areas

- around

- AS

- At

- away

- back

- Balance

- Baseline

- basis

- bbc

- BE

- Beauty

- because

- become

- becoming

- been

- behind

- being

- between

- Blue

- Branch

- branches

- but

- by

- CAN

- centre

- Chair

- City

- claimed

- Close

- CO

- compare

- concrete

- considered

- Conspiracy

- Convex

- Corner

- could

- course

- definitely

- depends

- describe

- deserves

- difficult

- dimensions

- discussion

- do

- does

- done

- down

- drawing

- each

- earth

- easy

- either

- eliminate

- engineer

- Engineering

- English

- enough

- Errors

- Ether (ETH)

- Event

- Every

- evolution

- example

- eye

- facing

- fascinating

- few

- File

- finds

- flat

- Floor

- Foot

- For

- found

- FRAME

- from

- fulfillment

- gap

- given

- Goes

- good

- grew

- Ground

- had

- Hard

- Have

- having

- he

- Hills

- his

- history

- holds

- How

- HTTPS

- i

- idea

- if

- image

- in

- industry

- innovations

- instead

- into

- inventions

- IT

- items

- ITS

- itself

- joined

- jpg

- just

- known

- layers

- Leads

- leaving

- left

- legs

- Length

- like

- likely

- Line

- Lives

- Look

- LOOKS

- lost

- machine

- Machines

- made

- make

- Making

- many

- material

- max-width

- mentioned

- metal

- method

- Milton

- mind

- mine

- Modern

- monthly

- more

- most

- moves

- multiple

- my

- nearly

- necessity

- notwithstanding

- observation

- of

- on

- ONE

- operate

- operator

- or

- Other

- Others

- our

- own

- pairs

- part

- passes

- perfectly

- photo

- piece

- pieces

- plane

- plato

- Plato Data Intelligence

- PlatoData

- Popular

- portrait

- Precision

- pretty

- probably

- Problem

- process

- producing

- proved

- racers

- rather

- really

- record

- reference

- refined

- reflect

- regions

- remains

- repeat

- result

- right

- road

- round

- runs

- s

- Science

- see

- set

- several

- side

- significant

- Simon

- Simple

- simplicity

- since

- sits

- Sitting

- skill

- slow

- smooth

- So

- solved

- something

- somewhere

- speed

- standard

- standards

- starts

- stems

- Still

- STONE

- Story

- subsequent

- Surface

- tackling

- technique

- temporary

- tend

- test

- Testing

- than

- that

- The

- the UK

- the world

- their

- Them

- There.

- These

- they

- things

- this

- three

- Thus

- times

- to

- today

- together

- too

- tool

- tools

- Tops

- towards

- traditional

- tree

- truly

- TURN

- Turned

- two

- Uk

- unit

- until

- us

- use

- used

- using

- value

- very

- volume

- walk

- was

- Way..

- we

- when

- which

- while

- WHO

- widely

- will

- with

- without

- wood

- wooden

- Work

- worked

- world

- wrap

- you

- youtube

- zephyrnet