Which parts matter most?

If you’re responsible for maintenance, repair and operations (MRO) supplies inventory, that’s a key question to ask and answer. Inventory is an investment, and that investment needs to be managed. But all parts aren’t equal. Some are critical to operations or employee safety. Others are “nice to have” but not urgent.

That’s why it’s crucial to have a defined methodology for spare parts coupled with thorough understanding of spares criticality to your operations. It’s the best way to deliver strong, reliable performance. And it’s also how you can determine the optimal stocking level.

Why criticality matters to MRO inventory

Trying to manually review and assign a “Spares Criticality” score to each individual item is nearly impossible given the tens or hundreds of thousands of items maintained in many MRO inventories. We’ve worked with many clients to assign asset and equipment criticality, and experience shows us that there are real benefits to allocating criticality to spare parts. This type of information:

- Provides an accurate assessment of critical spares and the money invested in those parts

- Delivers transparency and visibility to critical and non-critical spares inventory for the organization

- Eliminates “out of stock” occurrences

- Reduces time spent looking for and ordering parts

- Reduces dormant/non-moving inventory

- Accelerates disposal of obsolete materials

- Improves stock allocation to improve space utilization

- Optimizes inventory costs by balancing inventory to operational demand

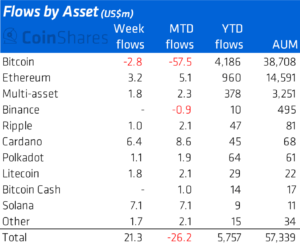

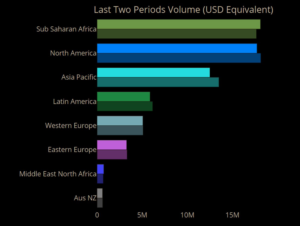

The two graphs below represent an average profile for a company’s in-depth review of their inventory:

Questions to ask for each spare part

It is important to point out, however, that just assigning a code to the spare part is not enough. There are variables that also need to be considered when you look at the criticality of a particular part. For example:

- What is the equipment on which this spare part would be used, and how critical is that equipment to operations?

- Who supplies this part? Is it an OEM or a third party?

- How much lead time is required to restock the part?

- In which warehouse is this part stored?

- Do you have the right Build of Materials (BOM)?

- Is the part used on multiple equipment types?

- What is the target service level?

- What are the work order priorities?

Once you decide which of the parameters above matter most to your organization, you then need to select a methodology and a solution that routinely audit those parameters. For example, any time a new transaction is created in the Enterprise Resource Planning (ERP), the solution needs to apply that transaction against the material to determine if the criticality is still correct.

Understanding Inventory Management Objectives

As you work to optimize your MRO inventory consider the following:

- If you want to provide customers with the maximum service level, what things may be done to improve that service levels and how does that affect any inventory decisions?

- Should you want to maintain the minimum level of inventory and achieve financial, budgetary or warehouse considerations, what methods can you employee to reduce those inventory levels?

- If your goal is to operate at the lowest cost and again, achieve financial or budgetary goals, what can you do to reduce those costs?

Explore the IBM MRO solution

IBM Maximo MRO Inventory Optimization can help you optimize your maintenance, repair and operations (MRO) inventory by providing an accurate, detailed picture of performance.

To help you understand just how important each part is, the MRO IO Material Criticality Value Service combines industry-leading MRO analytics technology and consulting expertise to provide relevant Spares Criticality.

Source: https://www.ibm.com/blogs/internet-of-things/mro-inventory-spares-criticality/

- All

- allocation

- analytics

- asset

- audit

- BEST

- build

- clients

- code

- consulting

- Costs

- Customers

- Enterprise

- equipment

- financial

- How

- HTTPS

- Hundreds

- IBM

- information

- inventory

- Inventory Management

- investment

- IT

- Key

- lead

- Level

- management

- materials

- Matters

- money

- Operations

- order

- Others

- performance

- picture

- planning

- Profile

- reduce

- resource

- review

- Safety

- Space

- stock

- Target

- Technology

- time

- transaction

- Transparency

- us

- value

- visibility

- Warehouse

- Work