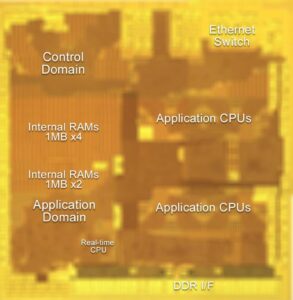

United Microelectronics Corporation, a global semiconductor foundry, has unveiled its 28eHV+ platform, the enhancement to its 28nm embedded high voltage (eHV) technology. Delivering greater power efficiency and visual quality, 28eHV+ is an ideal display driver solution to power next-generation displays used in smartphones, virtual and augmented reality devices, and IoT.

Compared to the proven 28nm eHV process, UMC’s 28eHV+ solution offers up to 15% reduction in power consumption without compromising image quality or data rates, addressing the demand for longer battery life of devices. It also offers optimised features to enable higher accuracy in voltage control and greater flexibility for chip designers.

For eHV technology, 28nm is currently the most advanced foundry process for small-panel display driver ICs (SDDI), used in AMOLED panels increasingly adopted in high-end smartphones and AR/VR devices. UMC is the foundry provider with over 85% of the 28nm SDDI market, having shipped more than 400 million units since volume production began in 2020.

“We are excited to introduce our 28eHV+ platform, which has already gained the interest of several customers and will enter production in the first half of 2023,” says Steven Hsu, UMC’s vice president of technology development. “As a leading provider of specialty foundry technologies, UMC offers differentiated solutions that are aligned with our customers’ roadmaps, enabling them to capture opportunities in fast-growing markets. Following the release of 28eHV+, our development teams will work on extending our display driver solutions to 22nm and beyond.”

UMC’s 28eHV+ technology features the small SRAM bit cells, reducing the chip area. It is based on the company’s 28nm gate-last High-K/Metal Gate technology, which features low leakage and dynamic power performance.

Comment on this article below or via Twitter: @IoTNow_OR @jcIoTnow

- SEO Powered Content & PR Distribution. Get Amplified Today.

- Platoblockchain. Web3 Metaverse Intelligence. Knowledge Amplified. Access Here.

- Source: https://www.iot-now.com/2023/03/06/128397-umc-introduces-28ehv-platform-for-wireless-vr-ar-iot-display-applications/

- :is

- $UP

- 15%

- 2020

- 2023

- a

- accuracy

- addressing

- adopted

- advanced

- aligned

- already

- and

- applications

- AR/VR

- ARE

- AREA

- article

- augmented

- Augmented Reality

- based

- battery

- Battery life

- began

- below

- Beyond

- Bit

- capture

- Cells

- chip

- Company’s

- compromising

- consumption

- control

- Currently

- Customers

- data

- delivering

- Demand

- designers

- Development

- Devices

- differentiated

- Display

- displays

- driver

- dynamic

- efficiency

- embedded

- enable

- enabling

- Enter

- excited

- extending

- Features

- First

- Flexibility

- following

- For

- Foundry

- Global

- greater

- Half

- having

- High

- High-End

- higher

- HTTPS

- ICS

- ideal

- image

- in

- increasingly

- interest

- introduce

- Introduces

- iot

- IT

- ITS

- jpg

- leading

- Life

- longer

- Low

- Market

- Markets

- million

- more

- most

- next-generation

- of

- Offers

- on

- opportunities

- Optimised

- panels

- performance

- platform

- plato

- Plato Data Intelligence

- PlatoData

- power

- president

- process

- Production

- proven

- provider

- quality

- Rates

- Reality

- reducing

- release

- roadmaps

- says

- semiconductor

- several

- shipped

- since

- small

- smartphones

- solution

- Solutions

- Specialty

- teams

- Technologies

- Technology

- Technology Development

- that

- The

- Them

- to

- units

- unveiled

- Vice President

- Virtual

- Voltage

- volume

- which

- will

- wireless

- with

- without

- Work

- zephyrnet