If you do much practical 3D printing, you eventually need some sort of fastener. You can use a screw to bite into plastic. You can create a clearance hole to accommodate a bolt and a nut or even build in a nut trap. You can also heat-set threaded inserts. Which is the best? [Thomas] does his usual complete examination and testing of the options in a recent video you can watch below.

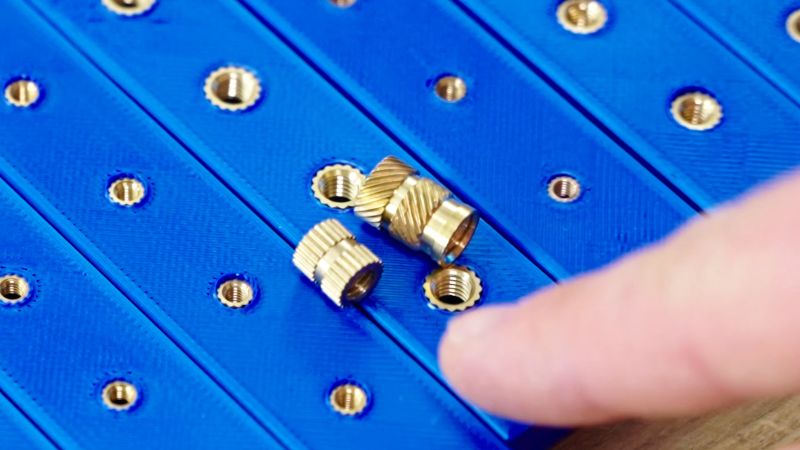

[Thomas] uses inserts from [CNCKitchen] and some cheap inserts for 3D printing and some for injection molding. There are differences in the configuration of the teeth that bite into the plastic. [Thomas] also experimented with thread adapters that grab a 3D-printed thread.

Of course, the real question is, do you even need the inserts? You can simply print threads in holes and forget all the extra parts. But will it be strong? Does the orientation of the thread matter?

As always, the end of the video summarizes the results. As you might expect, all of the inserts fail to allow the proper preload on the fasteners, so they will not achieve their maximum strength. However, there is more work to do to figure out the influence of infill and several other parameters.

[CNCKitchen] had a similar review if you want a second opinion. Or, you can read our take on it.

[embedded content]

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://hackaday.com/2024/01/06/thomas-sanladerer-gets-new-threads/

- :is

- :not

- 3d

- 3D Printing

- a

- accommodate

- Achieve

- All

- allow

- also

- always

- and

- ARE

- AS

- BE

- below

- BEST

- Bolt

- build

- but

- CAN

- cheap

- clearance

- Configuration

- content

- course

- create

- differences

- do

- does

- embedded

- end

- Even

- eventually

- examination

- expect

- extra

- FAIL

- Figure

- For

- from

- grab

- had

- his

- Hole

- Holes

- However

- HTTPS

- if

- in

- influence

- Inserts

- into

- IT

- Matter

- maximum

- might

- more

- much

- Need

- New

- of

- on

- Opinion

- or

- Other

- out

- parameters

- parts

- plastic

- plato

- Plato Data Intelligence

- PlatoData

- Practical

- printing

- proper

- question

- Read

- real

- recent

- Results

- Second

- several

- similar

- simply

- So

- some

- strength

- strong

- Take

- Testing

- that

- The

- their

- There.

- they

- to

- use

- uses

- usual

- Video

- want

- Watch

- which

- will

- with

- Work

- you

- youtube

- zephyrnet