In today’s environmentally-conscious era, industries worldwide are under scrutiny for their carbon footprint. One such industry is cement production, a significant contributor to greenhouse gas (GHG) emissions.

However, a beacon of hope emerges from this scenario: Sublime Systems. This innovative startup is on a mission to redefine cement production, making it greener and more sustainable.

Why is Sublime Systems a Potential Game-Changer?

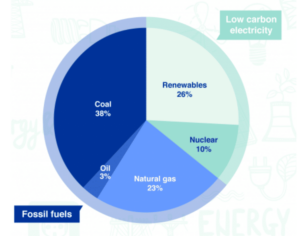

For those unfamiliar with the environmental impact of cement, it’s worth noting that traditional cement production accounts for about 8% of global GHG emissions. This alarming statistic underscores the urgent need for sustainable solutions.

Enter Sublime Systems, a company that is pioneering a revolutionary method of producing cement using electrochemistry.

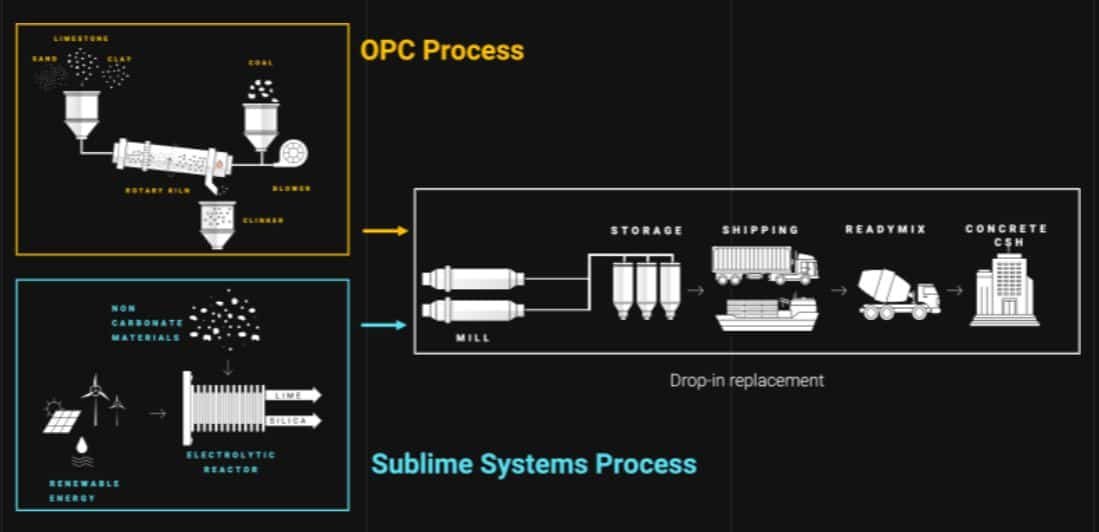

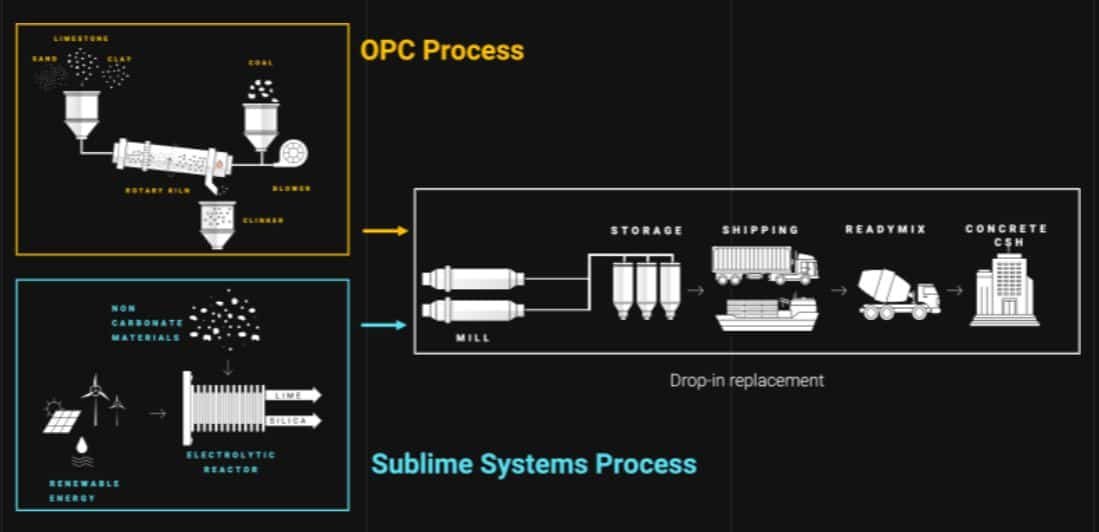

To appreciate the groundbreaking work of Sublime Systems, it’s essential to understand the conventional cement-making process and its environmental challenge.

Cement, when combined with water, sand, and gravel, forms concrete – the world’s second-most-used substance after water. This process has been unchanged for centuries:

- Raw materials, primarily limestone and clay, are heated in kilns to temperatures exceeding 1,400 °C (2,500 °F).

- Achieving these temperatures necessitates the burning of coal or other fossil fuels, leading to substantial carbon dioxide emissions.

- The chemical reactions in the kilns further release carbon dioxide, which often escapes into the atmosphere, exacerbating the greenhouse effect.

Sublime’s Innovative Approach: A Deep Dive

The Massachusetts-based company is not merely tweaking the existing process; they’re reinventing it. Their method hinges on two primary innovations:

- Electrochemical Reactions: Instead of relying on high temperatures, Sublime uses electrochemical reactions to produce cement. This approach eliminates the need for burning fossil fuels, significantly reducing carbon emissions.

- Renewable Energy Integration: By using electricity to fuel these reactions, Sublime’s plants can potentially harness renewable energy sources like solar and wind. This shift not only reduces emissions but also aligns with global renewable energy goals.

While their process is unique, what Sublime produces still adheres to strict industry standards. They’re producing high-performance, low-carbon cement that has similar strength, durability, slump, and set time as the cement used today. Their fossil-fuel-free cement has obtained ASTM C1157 designation, a performance-based industry standard.

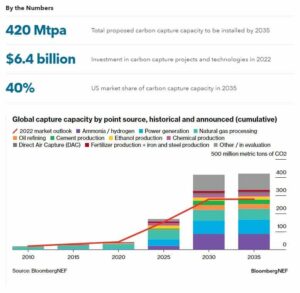

Because their system avoids carbon emissions altogether, there’s no extra expense needed. There’s also no need for using carbon capture, utilization, and storage (CCUS) technology.

Sublime’s technology innovations enable them to finally make a true zero-carbon cement for millennia to come. Its environmental benefits cannot be overstated. If successfully scaled, their method could slash cement-related emissions by an impressive 90%.

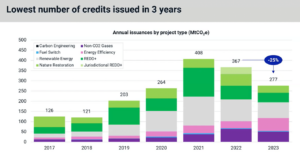

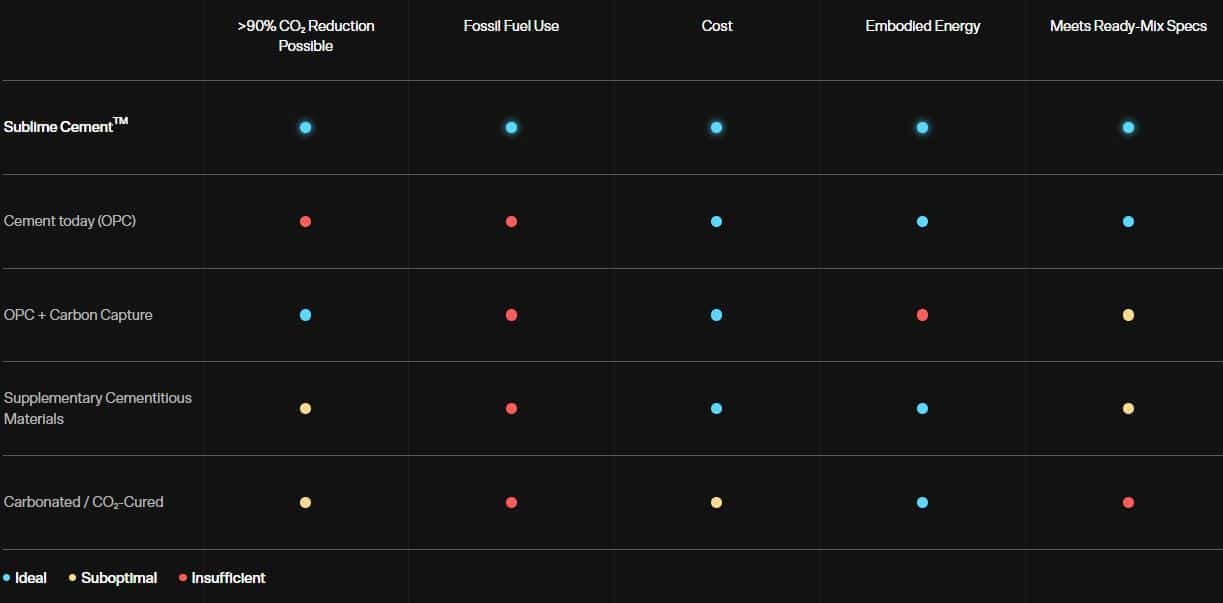

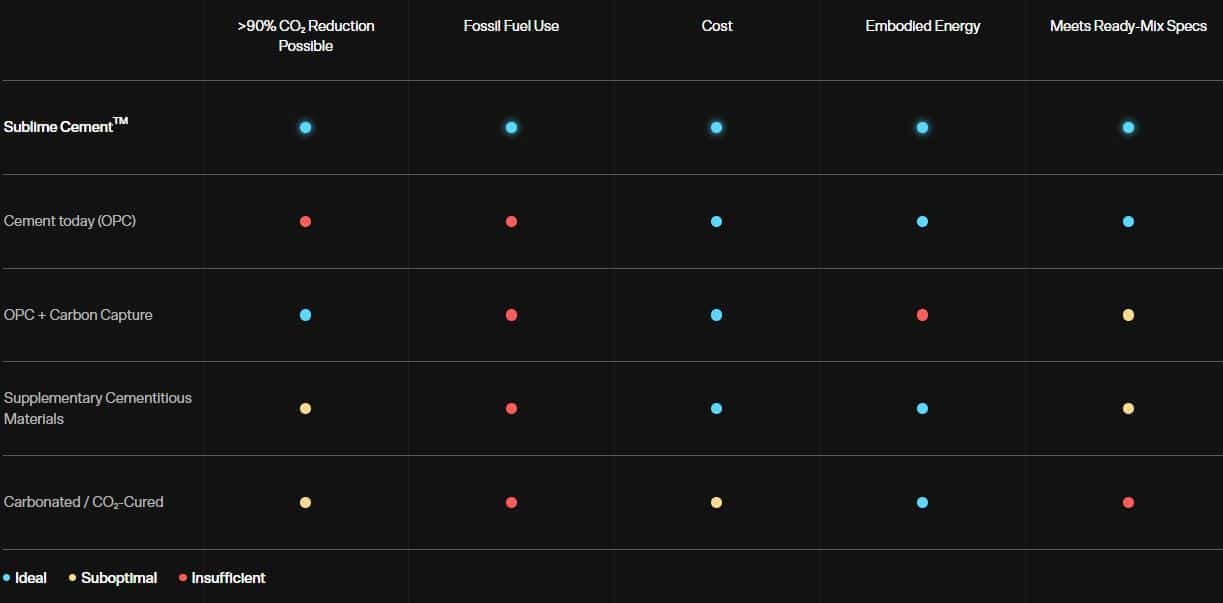

Moreover, by potentially offering cost-competitive solutions, Sublime presents a compelling economic and environmental case for its adoption in the broader industry. Here’s how the startup’s cement product compares to other systems.

Challenges and Future Prospects

Innovation, while exciting, often comes with hurdles. Sublime’s cement, though functionally similar to traditional cement, has a unique production pathway. This difference might be met with skepticism in the traditionally conservative construction sector.

New materials and technologies face rigorous testing and validation before gaining widespread acceptance.

Additionally, scaling up electrochemical processes is no small feat. It presents potential engineering challenges, from ensuring consistent reactions in larger tanks to procuring the necessary equipment for mass production. These challenges, coupled with the need for substantial capital investment, mean that Sublime’s journey ahead is both promising and demanding.

Despite this, Sublime Systems has showcased remarkable progress. From humble beginnings with small-scale reactions in an MIT lab, they’ve evolved to a pilot facility producing around 100 tons of cement annually. Their roadmap is ambitious, with plans for a larger facility by 2026 and a full-scale commercial plant by 2028.

In the interim, Sublime is focused on real-world testing. They aim to construct installations using their cement, from sidewalks to patios, to validate their product’s quality and durability.

Industry estimates show that 70% of the infrastructure needed by 2050 to house the growing population remains unbuilt. This calls for a challenging balance between global construction goals with emissions reductions targets.

A low-carbon innovation like Sublime’s becomes crucial to both meet such infrastructure demand as well as the performance of cement production standards.

Sublime Systems stands at the forefront of a green revolution in cement production. If successful, their innovative approach could set a new industry standard, blending sustainability with functionality. As the world grapples with the pressing challenge of climate change, companies like Sublime Systems offer a glimmer of hope, leading the way towards a more sustainable future.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://carboncredits.com/revolutionizing-cement-with-electrochemistry-the-sublime-way/

- :has

- :is

- :not

- $UP

- 1

- 100

- 2026

- 2028

- 2050

- 400

- 500

- a

- About

- acceptance

- Accounts

- Adoption

- After

- ahead

- aim

- Aligns

- also

- altogether

- ambitious

- an

- and

- Annually

- appreciate

- approach

- ARE

- AS

- At

- Atmosphere

- Balance

- BE

- beacon

- becomes

- been

- before

- benefits

- between

- blending

- both

- broader

- burning

- but

- by

- Calls

- CAN

- cannot

- capital

- carbon

- carbon dioxide

- carbon emissions

- carbon footprint

- case

- centuries

- challenge

- challenges

- challenging

- change

- chemical

- Climate

- Climate change

- Coal

- combined

- come

- comes

- commercial

- Companies

- company

- compelling

- conservative

- consistent

- construct

- construction

- contributor

- conventional

- could

- coupled

- crucial

- data

- deep

- Demand

- demanding

- difference

- durability

- Economic

- effect

- electricity

- eliminates

- emerges

- Emissions

- enable

- energy

- Engineering

- ensuring

- environmental

- equipment

- Era

- essential

- estimates

- evolved

- exciting

- existing

- extra

- Face

- Facility

- feat

- Finally

- focused

- Footprint

- For

- forefront

- forms

- fossil

- fossil fuels

- from

- Fuel

- fuels

- full-scale

- functionality

- functionally

- further

- future

- gaining

- game-changer

- GAS

- GHG

- GHG emissions

- glimmer

- Global

- Goals

- Green

- greener

- greenhouse gas

- groundbreaking

- Growing

- harness

- High

- high-performance

- hinges

- hope

- House

- How

- http

- HTTPS

- humble

- Hurdles

- if

- Impact

- impressive

- in

- industries

- industry

- industry standards

- Infrastructure

- Innovation

- innovations

- innovative

- instead

- interim

- into

- investment

- IT

- ITS

- journey

- jpg

- lab

- larger

- leading

- like

- low-carbon

- make

- Making

- Mass

- materials

- max-width

- mean

- Meet

- merely

- met

- method

- might

- Mission

- MIT

- more

- necessary

- Need

- needed

- New

- no

- noting

- obtained

- of

- offer

- offering

- often

- on

- ONE

- only

- or

- ordinary

- Other

- overstated

- pathway

- performance

- pilot

- Pioneering

- plans

- plant

- plants

- plato

- Plato Data Intelligence

- PlatoData

- population

- Portland

- potential

- potentially

- presents

- pressing

- primarily

- primary

- process

- processes

- produce

- produces

- producing

- Product

- Production

- Progress

- promising

- quality

- reactions

- real world

- redefine

- reduces

- reducing

- reductions

- release

- relying

- remains

- remarkable

- Renewable

- renewable energy

- Revolution

- revolutionary

- Revolutionizing

- rigorous

- roadmap

- SAND

- scaling

- scenario

- scrutiny

- sector

- set

- shift

- show

- showcased

- significant

- significantly

- similar

- Skepticism

- Slump

- small

- solar

- Solutions

- Sources

- standard

- standards

- stands

- startup

- Still

- storage

- strength

- strict

- substance

- substantial

- successful

- Successfully

- such

- Sustainability

- sustainable

- sustainable future

- system

- Systems

- Tanks

- targets

- Technologies

- Technology

- Technology Innovations

- Testing

- that

- The

- the world

- their

- Them

- These

- they

- this

- those

- though?

- time

- to

- today

- today’s

- towards

- traditional

- traditionally

- true

- tweaking

- two

- under

- underscores

- understand

- unfamiliar

- unique

- urgent

- used

- uses

- using

- VALIDATE

- validation

- vs

- W3

- Water

- Way..

- webp

- WELL

- What

- when

- which

- while

- widespread

- wind

- with

- Work

- world

- world’s

- worldwide

- worth

- zephyrnet