Reconfigurable FeHEMT

Researchers at the University of Michigan created a reconfigurable ferroelectric transistor that could enable a single amplifier to do the work of multiple conventional amplifiers.

“By realizing this new type of transistor, it opens up the possibility for integrating multifunctional devices, such as reconfigurable transistors, filters and resonators, on the same platform—all while operating at very high frequency and high power,” said Zetian Mi, U-M professor of electrical and computer engineering. “That’s a game changer for many applications.”

The ferroelectric high electron mobility transistor (FeHEMT) is made of aluminum nitride doped with scandium (ScAlN) and was grown using molecular beam epitaxy. The researchers say it is the first nitride-based ferroelectric semiconductor, enabling it to be integrated with gallium nitride (GaN).

“By adding ferroelectricity to an HEMT, we can make the switching sharper. This could enable much lower power consumption in addition to high gain, making for much more efficient devices,” said Ping Wang, a research scientist in electrical and computer engineering at U-M.

“We can make our ferroelectric HEMT reconfigurable,” added Ding Wang, a research scientist in electrical and computer engineering at U-M. “That means it can function as several devices, such as one amplifier working as several amplifiers that we can dynamically control. This allows us to reduce the circuit area and lower the cost as well as the energy consumption.”

The team says the device could be used for reconfigurable radio frequency and microwave communication as well as memory devices.

Fully epitaxial, monolithic ScAlN/AlGaN/GaN ferroelectric HEMT: https://doi.org/10.1063/5.0143645

Fluxonium qubit

Researchers from Lawrence Berkeley National Laboratory, University of California Berkeley, and Yale University propose that fluxonium qubits could form the basis for new fault-tolerant quantum processors and presented a systematic theoretical study of how to engineer fluxonium qubits for higher performance.

A type of superconducting qubit, the fluxonium circuit is composed of three elements: a capacitor, a Josephson Junction, and a superinductor, which helps suppress magnetic flux noise.

Key to the fluxonium qubit’s potential is its high anharmonicity, which refers to the difference between relevant transition frequencies in a qubit. This enables better qubit control because there’s less overlap between the frequencies that control the qubits and those that drive any given qubit to higher energy levels. The qubit also appears to have long coherence times.

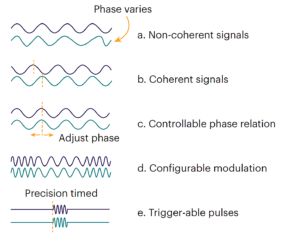

The team leading the fluxonium-based architecture focused on the scalability and adaptability of the processor’s main components, with a set of parameters that researchers can tune to increase the runtime and fidelity of quantum circuits. Some of these adaptations allow simpler operation of the system. One of the things the researchers proposed was controlling the fluxonium qubits at low frequency (1-GHz) via microwave pulses directly generated by an electrical arbitrary waveform generator. This approach would allow researchers to design processors and set up multiple qubits flexibly.

“We provided a potential path towards building fluxonium processors with standard, practical procedures to deploy logic gates with varying frequencies. We hope that more R&D on fluxonium and superconducting qubit alternatives will bring about the next generation of devices for quantum information processing,” said Long B. Nguyen, a project scientist at the Advanced Quantum Testbed (AQT) at Berkeley Lab.

Blueprint for a High-Performance Fluxonium Quantum Processor: https://doi.org/10.1103/PRXQuantum.3.037001

Recyclable printed electronics made using water

Engineers at Duke University produced fully recyclable printed electronics that replace the use of chemicals with water in the fabrication process.

Previously, the researchers created devices using three carbon-based inks: semiconducting carbon nanotubes, conductive graphene, and insulating nanocellulose. However, when adapting the fabrication process to use water, the carbon nanotubes presented a problem.

To make a water-based ink in which the carbon nanotubes don’t clump together and spread evenly on a surface, a surfactant similar to detergent is added. The resulting ink, however, does not create a layer of carbon nanotubes dense enough for a high current of electrons to travel across.

“You want the carbon nanotubes to look like al dente spaghetti strewn down on a flat surface,” said Aaron Franklin, the Addy Professor of Electrical and Computer Engineering at Duke. “But with a water-based ink, they look more like they’ve been taken one-by-one and tossed on a wall to check for doneness. If we were using chemicals, we could just print multiple passes again and again until there were enough nanotubes. But water doesn’t work that way. We could do it 100 times and there’d still be the same density as the first time.”

This is because the surfactant used to keep the carbon nanotubes from clumping also prevents additional layers from adhering to the first. In a traditional manufacturing process, these surfactants would be removed using either very high temperatures, which takes a lot of energy, or harsh chemicals, which can pose human and environmental health risks. Franklin and his group wanted to avoid both.

Instead, they turned to a process that involves rinsing the device with water, drying in relatively low heat, and printing on again.

Nearly 100% of the carbon nanotubes and graphene used in printing can be recovered and reused in the same process, losing very little of the substances or their performance viability. The nanocellulose can be recycled or biodegraded like paper.

“The performance of our thin-film transistors doesn’t match the best currently being manufactured, but they’re competitive enough to show the research community that we should all be doing more work to make these processes more environmentally friendly,” Franklin said.

All-Carbon Thin-Film Transistors Using Water-Only Printing: https://doi.org/10.1021/acs.nanolett.2c04196

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoAiStream. Web3 Data Intelligence. Knowledge Amplified. Access Here.

- Minting the Future w Adryenn Ashley. Access Here.

- Source: https://semiengineering.com/research-bits-may-2/

- :is

- :not

- $UP

- 100

- a

- Aaron

- About

- across

- Adaptations

- added

- adding

- addition

- Additional

- advanced

- AL

- All

- allows

- also

- alternatives

- an

- and

- any

- applications

- approach

- architecture

- AREA

- AS

- At

- avoid

- basis

- BE

- Beam

- because

- been

- being

- Berkeley

- BEST

- Better

- between

- both

- bring

- Building

- but

- by

- california

- CAN

- carbon

- carbon nanotubes

- Changer

- check

- chemicals

- Communication

- community

- competitive

- components

- composed

- computer

- Computer Engineering

- consumption

- control

- controlling

- conventional

- Cost

- could

- create

- created

- Current

- Currently

- density

- deploy

- Design

- device

- Devices

- difference

- directly

- do

- does

- Doesn’t

- doing

- Dont

- down

- drive

- Duke

- duke university

- dynamically

- efficient

- either

- Electronics

- electrons

- elements

- enable

- enables

- enabling

- energy

- Energy Consumption

- engineer

- Engineering

- enough

- environmental

- environmentally

- environmentally friendly

- fidelity

- filters

- First

- first time

- flat

- FLUX

- focused

- For

- form

- Frequency

- friendly

- from

- fully

- function

- Gain

- game

- game-changer

- Gates

- generated

- generation

- generator

- given

- Graphene

- Group

- grown

- Have

- Health

- helps

- High

- high-performance

- higher

- his

- hope

- How

- How To

- However

- HTTPS

- human

- if

- in

- Increase

- information

- integrated

- Integrating

- IT

- ITS

- just

- Keep

- lab

- laboratory

- layer

- layers

- leading

- levels

- like

- little

- Long

- Look

- look like

- losing

- Lot

- Low

- made

- Main

- make

- Making

- manufactured

- manufacturing

- many

- Match

- May..

- means

- Memory

- Michigan

- mobility

- molecular

- Monolithic

- more

- more efficient

- much

- multiple

- National

- New

- next

- Nguyen

- Noise

- of

- on

- ONE

- opens

- operating

- operation

- or

- our

- Paper

- parameters

- passes

- path

- performance

- ping

- plato

- Plato Data Intelligence

- PlatoData

- possibility

- potential

- power

- Practical

- presented

- Problem

- procedures

- process

- processes

- processing

- Processor

- processors

- Produced

- Professor

- project

- propose

- proposed

- provided

- Quantum

- quantum information

- Qubit

- qubits

- R&D

- Radio

- realizing

- reduce

- refers

- relatively

- relevant

- Removed

- replace

- research

- Research Community

- researchers

- resulting

- risks

- Said

- same

- say

- says

- Scalability

- Scientist

- semiconductor

- set

- several

- should

- show

- similar

- single

- some

- spread

- standard

- Still

- Study

- such

- Surface

- system

- takes

- team

- that

- The

- their

- theoretical

- There.

- These

- they

- things

- this

- those

- three

- time

- times

- to

- together

- tossed

- towards

- traditional

- transition

- travel

- Turned

- type

- university

- University of California

- university of california berkeley

- University of Michigan

- us

- use

- used

- using

- very

- via

- viability

- Wall

- want

- wanted

- was

- Water

- Way..

- we

- WELL

- were

- when

- which

- while

- will

- with

- Work

- working

- would

- zephyrnet