Identify and assess unexpected anomalies with Klika Tech, STMicroelectronics, DHElectronics and AWS

Determining the right anomaly detection solution is often a challenge

Industrial organizations with operations spread across multiple locations often struggle with the complexity of predicting, finding, and fixing equipment anomalies before they become costly catastrophes. Just trying to make sense of the enormous data volumes generated by regular industrial processes can be difficult enough.

Without a customized, right-sized IIoT solution in place to sift through the wide array of datasets produced by sensors and devices, unexpected anomalies can go undetected. The longer some of these go undetected, the greater the threat of increased operating costs, decreased productivity, unplanned downtime, and even eventual equipment failure.

Yet understanding the specific maintenance and condition monitoring needs of individual pieces of equipment, operating in different locations, presents its own obstacles when trying to envision, design, and implement the rightsized IIoT solutions.

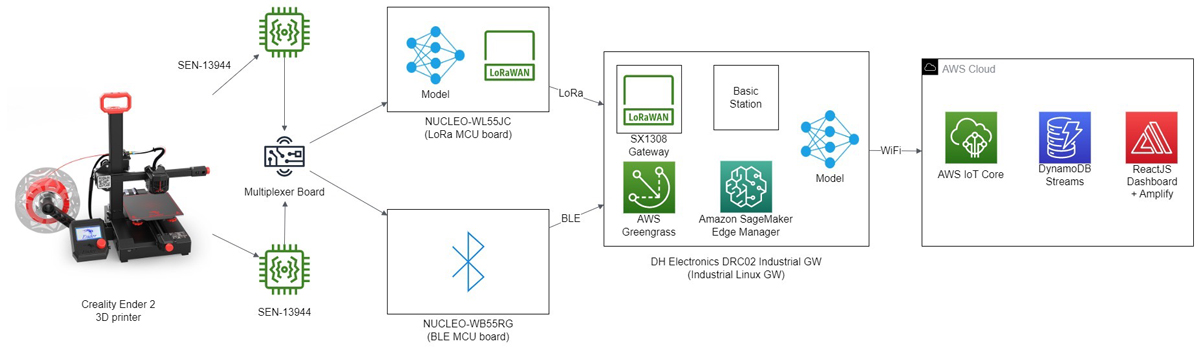

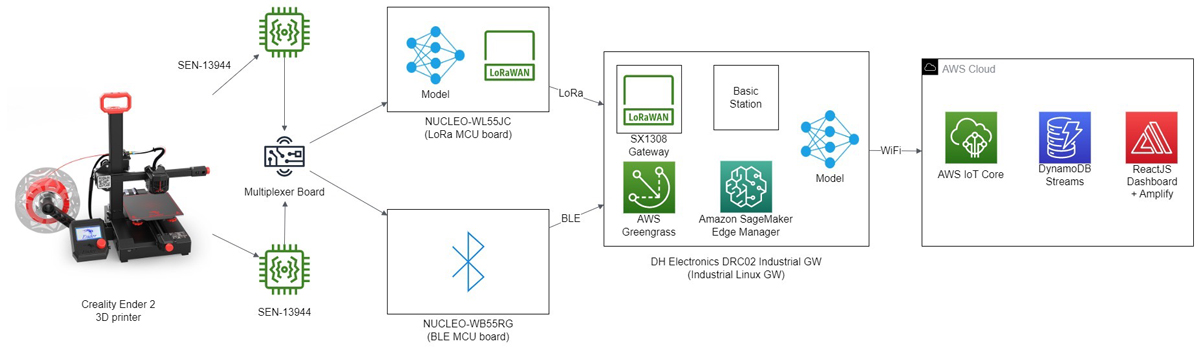

Klika Tech collaborated with STMicroelectronics, DHElectronics and AWS to develop a solution that finds actionable insights in collected data. This offering is based on an edge-to-cloud platform blueprint that lays out how ML models should run and is the core of the IIoT Anomaly Development solution accelerator that use STMicroelectronics microcontrollers to pre-process machine-level data at the edge for early anomaly detection.

Discover how tinyML models help organizations begin to think of IIoT data as an asset

- Maximize your ML investments

Enable edge sensors and devices to do more than just collect and manage data with ML at the machine level. - Predictive maintenance prevents mishaps

Extend the value of industrial equipment investments with regular monitoring and maintenance - Don’t repeat the same mistakes

Anomaly notifications are sent to AWS for future analysis by operators - Seamless AWS integration

Cloud-native secure integration with AWS products and services

Unify edge-to-cloud data collection & management to better detect and analyze anomalies

Built on a flexible architecture designed to pre-process data and detect equipment-level anomalies, the edge-to-cloud data collection and management solution accelerator developed by Klika Tech and ST Microelectronics runs tinyML at the edge to find abnormal behavior.

Gain performance visibility to extend the lifecycles of industrial equipment

This solution accelerator is managed by a DH Electronics DRC02 industrial gateway with Amazon Greengrass Version 2 running on STM32MP1 Series microprocessor. The STMicroelectronics P-NUCLEO-WB55 board collects the accelerometer sensor data from the printer and provides it to the anomaly detection model on the Gateway over BLE. In parallel, the STMicroelectronics P-NUCLEO-WL55 runs a TinyML anomaly detection model directly and sends the results to the cloud over LoRaWAN.

Having readily addressed those integral early steps in the process, Amazon SageMaker then enables ML model training, and ensures ongoing ML model optimization at the edge by bringing Amazon SageMaker NEO and Amazon SageMaker Edge Manager to the fold for model optimization and management. The visualization of sensor-to-cloud equipment performance—including system fault evaluation and predictive analytics—is displayed on a custom AWS Amplify-based dashboard.

Uncover hidden IIoT data insights on industrial equipment to detect unexpected anomalies

You cannot fix problems you are unaware of or prevent the proliferation of threats you cannot see. You can, however, avoid such scenarios by deploying Klika Tech’s solution accelerator to collect and manage data, powering it with STMicroelectronics connected sensors, and analyzing the collected data on AWS:

- Detect and assess anomalies hidden within IIoT data

- Ensure access to the most recent, valid equipment condition monitoring data to always have a complete view of relevant status details

- Get alerts on improper installations and fix to stem problems and increase ROI

- Reduce latency from edge-to-cloud to improve ML model data pre-processing, and sensor/device data collection and management

Getting started

Work with Klika Tech to visualize the ideal IIoT environment, then tap into our development knowledge and expertise to make it a reality.

Take the first step by contacting Klika Tech.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://www.iot-now.com/2024/01/10/141705-optimise-industrial-equipment-performance-with-anomaly-detection-fueled-by-edge-ml-models/

- :is

- 110

- 7

- 9

- a

- accelerator

- access

- across

- addressed

- alerts

- always

- Amazon

- Amazon SageMaker

- an

- analysis

- analyze

- analyzing

- and

- anomaly detection

- architecture

- ARE

- Array

- AS

- assess

- At

- avoid

- AWS

- based

- BE

- become

- before

- begin

- behavior

- Better

- blueprint

- board

- Bringing

- by

- CAN

- cannot

- catastrophes

- Cloud

- collaborated

- collect

- collection

- collects

- complete

- complexity

- condition

- connected

- Core

- costly

- Costs

- custom

- customized

- dashboard

- data

- datasets

- decreased

- deploying

- Design

- designed

- detect

- Detection

- develop

- developed

- Development

- Devices

- different

- difficult

- directly

- displayed

- do

- downtime

- Early

- Edge

- Electronics

- enables

- enormous

- enough

- ensures

- Environment

- envision

- equipment

- Ether (ETH)

- evaluation

- Even

- eventual

- expertise

- extend

- Failure

- Find

- finding

- finds

- First

- Fix

- flexible

- For

- from

- fueled

- future

- gateway

- generated

- Go

- greater

- Have

- help

- Hidden

- How

- However

- HTTPS

- ideal

- implement

- improve

- in

- Increase

- increased

- individual

- industrial

- industrial equipment

- insights

- integral

- integration

- into

- Investments

- iot

- IT

- ITS

- jpg

- just

- knowledge

- Latency

- Lays

- Level

- lifecycles

- locations

- longer

- LoRaWAN

- machine

- maintenance

- make

- manage

- managed

- management

- Management Solution

- manager

- max-width

- ML

- model

- models

- monitoring

- more

- most

- multiple

- needs

- NEO

- news

- notifications

- now

- obstacles

- of

- offering

- often

- on

- ongoing

- operating

- Operations

- optimise

- optimization

- or

- organizations

- our

- out

- over

- own

- Parallel

- performance

- pieces

- Place

- platform

- plato

- Plato Data Intelligence

- PlatoData

- Powering

- predicting

- predictive

- presents

- prevent

- prevents

- problems

- process

- processes

- Produced

- productivity

- Products

- provides

- readily

- Reality

- recent

- regular

- relevant

- repeat

- Reports

- Results

- right

- Run

- running

- runs

- sagemaker

- same

- scenarios

- secure

- see

- sends

- sense

- sensor

- sensors

- sent

- Series

- should

- Sift

- solution

- Solutions

- some

- specific

- spread

- Status

- Stem

- Step

- Steps

- Struggle

- such

- system

- Tap

- tech

- than

- that

- The

- then

- These

- they

- think

- this

- those

- threat

- threats

- Through

- to

- Training

- trying

- understanding

- undetected

- Unexpected

- use

- valid

- value

- version

- View

- visibility

- visualization

- visualize

- volumes

- when

- wide

- with

- within

- you

- Your

- zephyrnet