The “once-in-a-generation” events of late have opened companies’ eyes to the importance of effective risk planning and management, and the vulnerability of their supply chains.

Coined by statistician Nassim Nicholas Tayeb, a “black swan” is a rare and unpredictable event that has a catastrophic impact on businesses and industries. Its inherent low probability of occurrence, combined with a high potential impact, makes it difficult to prepare for.

Nevertheless, 65% of companies globally operate at a basic level of risk management that can be effective against known risks, such as supplier bankruptcy, but not those that are unknown or difficult to predict. And, thanks to increasing global interconnectedness, geopolitical tensions and other sources of disruption, black swan events are increasing in frequency.

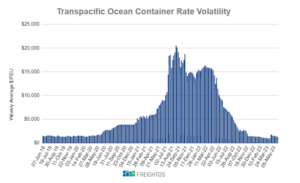

The long-term effect of a black swan event can be devastating to a company, and even entire economies. Among the most significant impacts are financial loss resulting from damage to infrastructure, less demand for a product or service, shortages in materials or parts, and lengthy delays in freight transportation.

Reputational damage can also follow, especially if an organization or the industry in which it operates is partly responsible for a black swan event. Companies are closely observed and judged on how they handle a catastrophic event for years to come.

Legal and regulatory challenges can follow if poor handling of the crisis by businesses or industries sparks investigations, adding additional costs and complexities before the return to “normal.”

Supplier diversification is among the most essential actions a business can take to survive a black swan event, but it requires prior planning. A multi-sourcing strategy incorporates businesses owned by diverse individuals or groups into the supply chain. Essentially, it serves as a form of insurance: if one domino becomes unstable, the entire line-up doesn’t fall.

Diversification can mean widening a supplier network to include domestic and international partners. Domestic suppliers usually charge more than global ones, primarily because they can offer shorter lead times and more flexible, personalized service. But during the chaos of a black swan event, they're less likely to let you down.

One of the most significant benefits of this approach is the ability to create a safety net if a supplier has difficulties and there’s a need to minimize disruption. For example, the Suez Canal obstruction in 2021 reduced Asian and European trade vessel capacity by 15% to 21%, but reliance on multiple suppliers would likely have lessened the economic implications.

In addition to the financial and logistical benefits, supplier diversification helps companies achieve social responsibility goals, supporting new and small businesses without drastically increasing supply chain risks. Following are some steps they can take to achieve those objectives.

Prioritize end-to-end due diligence. Maintenance of strict quality control is one of the procurement risk metrics that can be overlooked during a black swan event. However, it’s an essential component of effective procurement strategies.

Procurement professionals often focus heavily on supply chain disruption, supplier relationship management, and maverick spend, but they mustn’t forget the importance of quality control.

For example, in the event of a highly disruptive black swan event, the quick identification and onboarding of alternative suppliers is likely to take precedence over quality. To reduce the risk, organizations must ensure that their procurement strategies prioritize quality control, and that they have backup plans in place in the event of disruption.

At any time, businesses should measure and review supplier performance to ensure they’re meetiing key performance indicators. The CIPS Procurement Cycle is made up of 13 steps, starting at the request for proposals specification and finishing with asset management.

Supplier scorecards are a tangible way to guarantee product and service quality, timeliness of delivery, and other crucial KPIs. They help companies mitigate supply chain risks by avoiding costly issues like delays, missed deliveries and damaged goods.

Deploy specialist software. Increased use of specialist technology and software in procurement is predicted as a major trend for 2023, as artificial intelligence and automated systems become more widely adopted.

Resilient supply chains are built on shared information. Yet it can be difficult to analyze, interpret and act on without a central platform that gives 360-degree visibility. After all, with evaluation and monitoring work sitting across multiple emails, inboxes and documents, it's easy to miss something important, especially when crisis hits.

Sourcing and procurement platforms make managing supplier performance and monitoring supply chain stability easier. Centralized databases support capturing supplier data and compliance tracking, increasing visibility within the supplier-management ecosystem. Streamlined processes also reduce workload and save procurement teams precious time, while reducing the margin for human error.

The benefits stretch beyond risk management. By digitizing procurement processes, organizations can discover, assess, engage and monitor suppliers, enabling them to measure progress against key business priorities such as supply continuity; environmental, social and governance (ESG) performance and innovation.

Plan for pivots. To cope with black swan events, it’s essential that companies allow room for agile and flexible pivots in procurement.

The concept of “agile procurement” isn’t a new one. But its use has scaled up since the COVID-19 pandemic, despite critics such as Bill Gates (and Taleb himself) saying that was an entirely predictable if not inevitable event.

The many benefits of agile procurement include enabling businesses to make intelligent moves more quickly, allow more room for negotiation between partners, improve processes and introduce new technologies, enhance stakeholder accessibility and usability, and implement responsible strategies in accordance with real-time metrics.

No more making excuses because it’s “the way we’ve always done it.”

Jack Macfarlane is founder and chief executive officer of DeepStream.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- Platoblockchain. Web3 Metaverse Intelligence. Knowledge Amplified. Access Here.

- Source: https://www.supplychainbrain.com/blogs/1-think-tank/post/36658-how-to-manage-supply-chain-risk-in-the-age-of-unpredictability

- 2021

- 360-degree

- a

- ability

- accessibility

- Achieve

- across

- Act

- actions

- addition

- Additional

- adopted

- After

- against

- agile

- All

- alternative

- always

- among

- analyze

- and

- approach

- artificial

- artificial intelligence

- asian

- asset

- asset management

- Automated

- avoiding

- Backup

- Bankruptcy

- basic

- because

- become

- becomes

- before

- benefits

- between

- Beyond

- Bill

- Bill Gates

- Black

- built

- business

- businesses

- Capacity

- Capturing

- catastrophic

- central

- centralized

- chain

- chains

- challenges

- Chaos

- charge

- chief

- chief executive officer

- closely

- combined

- come

- Companies

- company

- complexities

- compliance

- component

- concept

- control

- Costs

- COVID-19

- COVID-19 pandemic

- create

- crisis

- Critics

- crucial

- data

- databases

- deep

- delays

- Deliveries

- delivery

- Demand

- Despite

- devastating

- difficult

- difficulties

- digitizing

- diligence

- discover

- Disruption

- disruptive

- diverse

- diversification

- documents

- Doesn’t

- Domestic

- down

- drastically

- during

- easier

- Economic

- economies

- ecosystem

- effect

- Effective

- emails

- enabling

- end-to-end

- engage

- ensure

- Entire

- entirely

- environmental

- error

- ESG

- especially

- essential

- essentially

- Ether (ETH)

- European

- evaluation

- Even

- Event

- events

- example

- executive

- Executive Officer

- Eyes

- Fall

- financial

- flexible

- Focus

- follow

- following

- form

- founder

- freight

- Freight Transportation

- Frequency

- from

- Gates

- geopolitical

- gives

- Global

- Globally

- Goals

- goods

- governance

- Group’s

- guarantee

- handle

- Handling

- heavily

- help

- helps

- High

- highly

- Hits

- How

- How To

- However

- HTTPS

- human

- Identification

- Impact

- Impacts

- implement

- implications

- importance

- important

- improve

- in

- include

- incorporates

- increasing

- Indicators

- individuals

- industries

- industry

- inevitable

- information

- Infrastructure

- inherent

- Innovation

- insurance

- Intelligence

- Intelligent

- International

- introduce

- Investigations

- issues

- IT

- judged

- Key

- known

- Late

- lead

- lessened

- Level

- likely

- long-term

- loss

- Low

- made

- make

- MAKES

- Making

- manage

- management

- managing

- many

- Margin

- materials

- maverick

- measure

- Metrics

- Mitigate

- Monitor

- monitoring

- more

- most

- moves

- multi-sourcing

- multiple

- Need

- net

- network

- New

- New technologies

- objectives

- offer

- Officer

- Onboarding

- ONE

- opened

- operate

- operates

- organization

- organizations

- Other

- owned

- pandemic

- partners

- parts

- performance

- Personalized

- Pivots

- Place

- planning

- plans

- platform

- Platforms

- plato

- Plato Data Intelligence

- PlatoData

- poor

- potential

- Precious

- predict

- Predictable

- predicted

- Prepare

- primarily

- Prior

- Prioritize

- probability

- processes

- Product

- professionals

- Progress

- Proposals

- quality

- Quick

- quickly

- RARE

- RE

- real-time

- reduce

- Reduced

- reducing

- regulatory

- relationship

- reliance

- request

- requires

- responsibility

- responsible

- resulting

- return

- review

- Risk

- risk management

- risks

- Room

- Safety

- Save

- serves

- service

- shared

- shortages

- should

- significant

- since

- Sitting

- small

- small businesses

- Social

- Software

- some

- something

- Sources

- Sparks

- specialist

- specification

- spend

- Stability

- stakeholder

- Starting

- Steps

- strategies

- Strategy

- streamlined

- strict

- such

- suppliers

- supply

- supply chain

- Supply chains

- support

- Supporting

- survive

- swan

- Systems

- Take

- teams

- Technologies

- Technology

- The

- their

- time

- times

- to

- Tracking

- trade

- transportation

- Trend

- unpredictable

- usability

- use

- usually

- Vessel

- visibility

- vulnerability

- which

- while

- widely

- within

- without

- Work

- would

- years

- zephyrnet