Floship, the global circular supply chain ecosystem solutions provider, has announced its participation in a key panel at the upcoming US leg of The Economist Impact’s global event series – the 3rd annual Sustainability Week US.

The event focuses on helping businesses become sustainable faster while taking advantage of green subsidies and will take place in a hybrid format on 30 May and 1 June virtually, with an in-person day on 31 May at the Renaissance Hotel, Downtown, Washington D.C.

Sustainability Week brings together executives, key decision, and policymakers from both private and public sectors and showcases the most practical strategies to turn sustainability plans into tangible actions. Furthermore, it analyses the success of not only best practices but also investigates the answers to difficult questions, such as making sustainability a priority across the entire organisation and its supply chains.

Floship CEO, Josh Tsui, will join a panel discussion, “The future is circular—how companies can work together on circular supply chains” that will explore key challenges that leading brands today must address to enable circular supply chain operations. Other panelists include senior supply chain and sustainability executives from eBay, Herman Miller, and Under Armour.

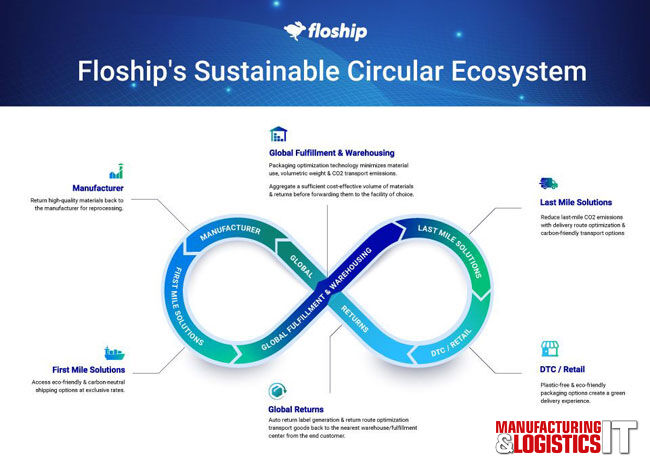

Floship will demonstrate its holistic circular supply chain solutions at the conference, illustrating how it connects every core component across the value chain from the manufacturer, warehouse systems, delivery mechanisms, and returns solutions through a wholly integrated platform.

The company’s intelligent portal incorporates a customer-based automated rule engine — enabling users to establish rules across their entire supply chain for a much more structured and smoother shipping process. The customisable automation rule engine makes supply chain management much simpler, minimises the risk of human-made errors, and is less time-consuming for ecommerce owners, enabling them to focus on maximising their brand’s growth opportunities.

Circular supply chains involve a company re-using or repurposing waste and customer returns to convert those resources into new or refurbished products. Circularity aims to minimise the use of raw materials and minimise discarded waste materials. Rather than discarding the waste generated at the end of the traditional linear supply chain, the waste (as well as customer returns) connects that endpoint back to the beginning creating a circular supply chain and cutting down on the need for new raw materials.

“Leading global organizations are waking up to the realisation that their supply chains can no longer be linear, which indicates a straight path from raw materials to production, and finally, to disposal,” said Tsui. “Organisations leveraging a more circular supply chain are utilising advanced e-commerce logistics technologies and strategies for discarded products to manufacture new ones. This new philosophy creates a process that helps consumers, businesses, and the economy to be more efficient with the limited amount of resources available in modern times.”

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoAiStream. Web3 Data Intelligence. Knowledge Amplified. Access Here.

- Minting the Future w Adryenn Ashley. Access Here.

- Buy and Sell Shares in PRE-IPO Companies with PREIPO®. Access Here.

- Source: https://www.logisticsit.com/articles/2023/05/22/floship-to-demonstrate-circular-supply-chain-solutions-at-sustainability-week-us

- :has

- :is

- :not

- $UP

- 1

- 30

- 3rd

- a

- across

- actions

- address

- advanced

- ADvantage

- aims

- also

- amount

- an

- and

- announced

- annual

- answers

- ARE

- AS

- At

- Automated

- Automation

- available

- back

- BE

- become

- Beginning

- BEST

- best practices

- both

- brand

- brands

- Brings

- businesses

- but

- CAN

- ceo

- chain

- chains

- challenges

- Companies

- company

- Company’s

- component

- Conference

- connects

- Consumers

- convert

- Core

- creates

- Creating

- customer

- customisable

- cutting

- day

- decision

- delivery

- demonstrate

- difficult

- discussion

- down

- Downtown

- e-commerce

- eBay

- ecommerce

- Economist

- economy

- ecosystem

- efficient

- enable

- enabling

- end

- Endpoint

- Engine

- Entire

- Errors

- establish

- Event

- Every

- executives

- explore

- faster

- Finally

- Focus

- focuses

- For

- format

- from

- Furthermore

- future

- generated

- Global

- Green

- Growth

- helping

- helps

- holistic

- hotel

- How

- HTTPS

- Hybrid

- in

- include

- incorporates

- indicates

- integrated

- Intelligent

- into

- investigates

- involve

- IT

- ITS

- join

- jpg

- june

- Key

- leading

- less

- leveraging

- Limited

- logistics

- longer

- MAKES

- Making

- management

- Manufacturer

- materials

- maximising

- May..

- mechanisms

- Miller

- minimise

- Modern

- more

- more efficient

- most

- much

- must

- Need

- New

- no

- of

- on

- ones

- only

- Operations

- opportunities

- or

- organisation

- organizations

- Other

- owners

- panel

- panel discussion

- participation

- path

- philosophy

- Place

- plans

- platform

- plato

- Plato Data Intelligence

- PlatoData

- policymakers

- Portal

- Practical

- practices

- priority

- private

- process

- Production

- Products

- provider

- public

- Questions

- rather

- Raw

- Renaissance

- Resources

- returns

- Risk

- Rule

- rules

- s

- Said

- Sectors

- senior

- Series

- Shipping

- smoother

- Solutions

- straight

- strategies

- structured

- success

- such

- supply

- supply chain

- supply chain management

- Supply chains

- Sustainability

- sustainable

- Systems

- Take

- taking

- Technologies

- than

- that

- The

- The Economist

- their

- Them

- this

- those

- Through

- time-consuming

- times

- to

- today

- together

- traditional

- TURN

- under

- upcoming

- us

- use

- users

- value

- virtually

- Warehouse

- washington

- Waste

- week

- WELL

- which

- while

- wholly

- will

- with

- Work

- work together

- zephyrnet