Copper nanowires that have been transformed into a foam can filter submicron-sized airborne particles with over 96.6% efficiency. The material, which is lightweight, resistant to chemicals and easy to clean, reuse and recycle, could be used in face masks as well as air cleaners to help fight the COVID-19 pandemic, according to the researchers at Georgetown University in the US who developed it.

In a study published in Nano Letters, Kai Liu and colleagues note that the current COVID-19 health crisis has highlighted the crucial role of submicron-sized airborne particles and particulates in the spread of infectious respiratory diseases. The virus that causes COVID-19, SARS-CoV-2 (severe acute respiratory syndrome coronavirus 2) is itself very small and measures around 0.1 μm across.

Ultrafine particles are a problem

When a person infected with the virus exhales (and especially if they also sneeze or cough), they release viral particles into the air. These particles are often attached to much larger droplets. Droplets and particles bigger than 2.5 μm generally have limited reach because they rapidly precipitate thanks to gravity. However, objects below this size (denoted as PM2.5), such as aerosolized viral particles, can remain suspended in the air for hours or even days and travel long distances, spreading the virus as they go. Ultrafine particles, 0.3 μm or smaller (PM0.3), are even more dangerous since they can penetrate deep into the respiratory system, with some even reaching the bloodstream.

The fibres on the surfaces of face masks bind these small particles to the mask via van der Waals forces. Charged fibres go a step further, binding the particles via electrostatic interactions. The problem is that the polymeric fibres typically employed in highly efficient particulate air (HEPA) filters and N95 face masks tend to degrade when exposed to UV radiation, solvents or chlorine-based solutions. This makes it hard to decontaminate and reuse them. The filtering efficiency of fibres that trap particles electrostatically also dramatically decreases once the masks become moist and the fibres discharge. Another important concern is the sheer volume of plastic-based waste currently being generated around the world in the form of used face masks.

Metallic foams are efficient filters

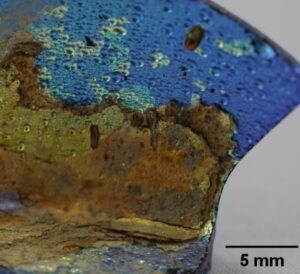

Researchers recently discovered that metallic foams might be effective filters for submicron-sized airborne particles. As well as being structurally robust – even to high temperatures and pressure – such materials are resistant to various organic solvents, corrosive chemicals and even UV radiation.

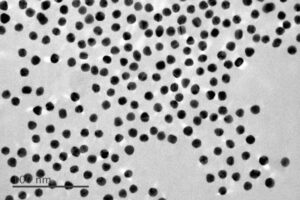

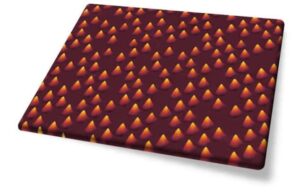

In their new work, Liu and colleagues fabricated metal foams by casting copper nanowires made using an electrodeposition technique into a free-standing three-dimensional network. They then solidified the structure by sintering it. Finally, they applied a second layer of copper (again using electrodeposition) to further strengthen the material.

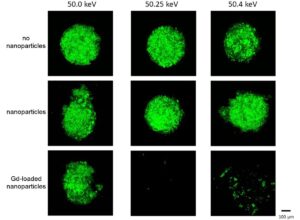

Excellent filtering for a broad range of particle sizes

The extremely large surface area of the foams makes them excellent filters for a broad range of particle sizes, including PM0.3. Indeed, the Georgetown team found that they efficiently filtered particles across the 0.1 to 1.6 μm size range. This is particularly relevant for fighting COVID-19, as aerosolized viral particles in this size range are most challenging to capture, they say.

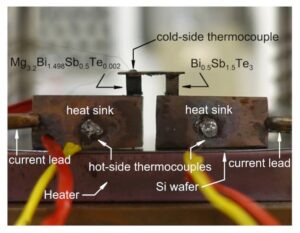

The most effective material they made was 2.5 mm thick and contained 15% by volume of copper. This foam trapped 97% of 0.1-0.4 μm aerosolized salt particles (which are commonly employed to test face masks) without the use of electrostatics. The breathability of the foams was generally on a par with, or even higher than, commercially available polypropylene N95 face masks (as tested using pressure differential measurements).

The researchers say the foams can easily be cleaned by rinsing them with water or blowing compressed air at them. And since the new material is based on copper, it should be recyclable and resistant to chemical-based cleaning products too. Copper is also naturally antimicrobial, so it should destroy viruses trapped on the filter surface.

The physics of N95 masks, imaging sensitive corals, how Fermilab’s PIP-II accelerator will work

The materials would currently cost around $2/mask, according to the researchers’ calculations, a figure that could be reduced further with mass production on an industrial scale. The fact that they can be disinfected and reused would also help make them economically competitive with currently-available products.

“Our results demonstrate a new type of efficient particulate filter, especially for submicron-size particulates such as the SARS-CoV-2 virus, and could potentially be used in face masks,” Liu says. “We now plan to explore a number of other filtration mechanisms that may further improve the foam’s filtration efficiency and enhance new functionalities in prototype filtration systems,” he tells Physics World.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoAiStream. Web3 Data Intelligence. Knowledge Amplified. Access Here.

- Minting the Future w Adryenn Ashley. Access Here.

- Buy and Sell Shares in PRE-IPO Companies with PREIPO®. Access Here.

- Source: https://physicsworld.com/a/copper-nanowire-foams-filter-tiny-airborne-particles/

- :has

- :is

- 1

- 10

- 15%

- 2021

- a

- accelerator

- According

- across

- adapted

- again

- AIR

- also

- an

- and

- Another

- applied

- ARE

- AREA

- around

- AS

- At

- available

- based

- BE

- because

- become

- been

- being

- below

- bigger

- bind

- binding

- Blowing

- broad

- by

- CAN

- capture

- causes

- challenging

- charged

- chemicals

- Cleaning

- colleagues

- commercially

- commonly

- competitive

- Concern

- contained

- Copper

- Coral

- Coronavirus

- Cost

- could

- COVID-19

- COVID-19 pandemic

- credit

- crisis

- crucial

- Current

- Currently

- Dangerous

- Days

- decreases

- deep

- demonstrate

- destroy

- developed

- discovered

- diseases

- dramatically

- easily

- easy

- Effective

- efficiency

- efficient

- efficiently

- employed

- enhance

- especially

- Even

- excellent

- explore

- exposed

- extremely

- Face

- face masks

- fact

- fight

- fighting

- Figure

- filter

- filtering

- filters

- Finally

- Foam

- For

- Forces

- form

- found

- from

- functionalities

- further

- generally

- generated

- Go

- gravity

- Hard

- Have

- he

- Health

- help

- High

- higher

- Highlighted

- highly

- HOURS

- How

- However

- HTTPS

- if

- image

- Imaging

- important

- improve

- in

- Including

- industrial

- information

- interactions

- into

- issue

- IT

- ITS

- itself

- jpg

- large

- larger

- layer

- lightweight

- Limited

- Long

- made

- make

- MAKES

- mask

- Masks

- Mass

- material

- materials

- max-width

- May..

- measurements

- measures

- mechanisms

- metal

- might

- more

- most

- much

- Nature

- network

- New

- now

- number

- objects

- of

- often

- on

- once

- or

- organic

- Other

- over

- pandemic

- particle

- particularly

- person

- Physics

- Physics World

- plan

- plato

- Plato Data Intelligence

- PlatoData

- potentially

- pressure

- Problem

- Production

- Products

- prototype

- published

- Radiation

- range

- rapidly

- reach

- reaching

- recently

- Reduced

- release

- relevant

- remain

- researchers

- resistant

- Respiratory Diseases

- Results

- reuse

- robust

- Role

- salt

- SARS-CoV-2

- say

- says

- Scale

- Second

- sensitive

- severe

- should

- since

- sits

- Size

- sizes

- small

- smaller

- So

- Solutions

- some

- someday

- spread

- Spreading

- Step

- Strengthen

- structure

- Study

- such

- Surface

- suspended

- system

- Systems

- team

- tells

- test

- than

- thanks

- that

- The

- the world

- their

- Them

- then

- These

- they

- this

- three-dimensional

- thumbnail

- to

- too

- transformed

- travel

- true

- type

- typically

- university

- us

- use

- used

- using

- various

- very

- via

- viral

- virus

- viruses

- volume

- was

- Waste

- Water

- WELL

- when

- which

- WHO

- will

- with

- without

- Work

- world

- would

- zephyrnet