Two new articles made the list of our most-read blogs for 2022. They join eight from last year’s top 10 covering a variety of topics including perspectives on equipment sterilization, firmware testing, and the impact of certain standards and compliances on labeling and vendor selection.

Two new articles made the list of our most-read blogs for 2022. They join eight from last year’s top 10 covering a variety of topics including perspectives on equipment sterilization, firmware testing, and the impact of certain standards and compliances on labeling and vendor selection.

How to identify a Conformité Européenne mark vs a China Export mark

The Conformité Européenne (CE) mark is a common sight on products in North America, and Europe. However, the China Export mark and CE mark are easily confused. Given the vast difference in the meaning of these symbols, engineers need to be able to tell them apart. In this blog Electrical Engineer, Ashwin Sira, explains the meaning of both marks and provides a simple way to differentiate them.

Qualifying and Managing RoHS and REACH suppliers

Companies manufacturing equipment or consumer parts that use hazardous materials in the manufacturing process must comply with RoHS and REACH environment regulations. Taimoor Khan discusses the importance of knowing which vendors are compliant.

Pros and cons of two popular Ultrasound signal processing techniques

Although there are several methods of demodulation in ultrasound, two ultrasound signal processing techniques are used predominately nowadays. Kenneth MacCallum, PEng, offers the pros and cons of both methods and concurs they will both likely be used for the foreseeable future.

RoHS 2 vs RoHS 3 impact on medical devices

The Restriction of Hazardous Substances (RoHS) has had a substantial and permanent effect on the materials that go into many of the electronic products we make. Nigel Syrotuck updated his original blog in late 2020 and explains how knowing what to look for and finding good vendors with appropriate quality programs will lead to a smoother product development program and faster time to market.

An electrical engineer’s overview of IEC 60601-1 Terminology & Definitions through Annexes

The list of standards that apply to the development of medical devices is extensive – and for good reason. In this blog Bjarne Hansen looks at one of the more important ones —IEC 60601-1— and explains each of it’s 16 sections.

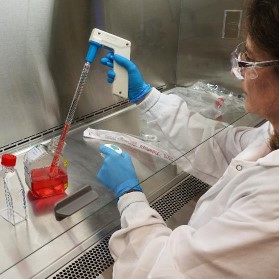

Determining the best method to detect E. coli

Selecting a method for developing an assay depends on the intended application and your target market. For instance, there are a variety of methods for detecting E. coli including PCR, gold nanoparticles, and fluorescent labelled enzymes – but it helps to know which to use when. In this blog Azra Raswani discusses these detection methods and what applications they are best suited for.

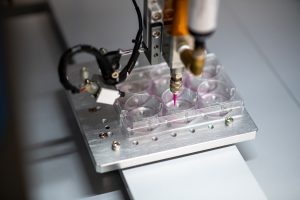

5 gamma irradiation sterilization tips

Selecting the right sterilization process for a medical device requires consideration at an early stage in development as characteristics like geometry, material composition, and construction all factor into the decision. Senior Systems Engineer, Julian Grove, provides an interesting case study about selecting the right sterilization process for a new disposable device and how gamma irradiation won out.

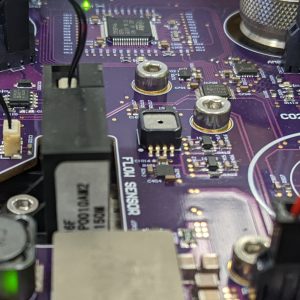

Unit testing in embedded systems: 3 myths and an automated tip

As embedded firmware becomes increasingly complex – especially with the proliferation of connected medical devices – unit testing could be the solution to quality control and device reliability. In this article Peter Kasakoff debunks three common myths about unit testing firmware and offers some advice for doing it right.

With their capacity to serve as a universal language, symbols are used to convey information on medical device labels around the world. In 2021 the International Organization for Standardization released an update to its standards documented in ISO 15223-1 including the addition of 25 new symbols. QA/RA manager, Deborah Pinchev, offers a helpful summary of the update and explains the new symbols.

Supplier Quality Agreement or Supply Agreement?

In the early stages of medical device development, it is usually sufficient to secure pre-production quantities through a simplified procurement cycle. A specification, a quote, a purchase order and a certificate of conformance —what other paperwork is needed? Why clutter up a simple, well-defined process with other documents and paperwork? Starfish Supply Chain Manager, Laura Meyer explains how launching a Supplier Quality Agreement early in the stage of development can help maintain quality in the supply chain early in the game.

Image Credits: see individual blogs

Astero StarFish is the attributed author of StarFish Medical team blogs. We value teamwork and collaboration on all of our medical device development projects.

[embedded content]

- SEO Powered Content & PR Distribution. Get Amplified Today.

- Platoblockchain. Web3 Metaverse Intelligence. Knowledge Amplified. Access Here.

- Source: https://starfishmedical.com/blog/medical-device-blogs/

- 10

- 2020

- 2021

- 2022

- a

- Able

- About

- addition

- advice

- Agreement

- All

- america

- and

- apart

- Application

- applications

- Apply

- appropriate

- around

- article

- articles

- author

- Automated

- becomes

- BEST

- Blog

- blogs

- Capacity

- case

- case study

- certain

- certificate

- chain

- characteristics

- China

- collaboration

- COM

- Common

- complex

- compliant

- confused

- connected

- Cons

- consideration

- construction

- consumer

- content

- control

- could

- covering

- Credits

- decision

- depends

- Detection

- developing

- Development

- device

- Devices

- difference

- differentiate

- Display

- documents

- doing

- E. coli

- each

- Early

- early stage

- easily

- effect

- Electronic

- embedded

- engineer

- Engineers

- Environment

- equipment

- especially

- Ether (ETH)

- Europe

- Explains

- export

- extensive

- faster

- finding

- foreseeable

- from

- future

- game

- given

- Go

- Gold

- good

- help

- helpful

- helps

- Hidden

- How

- However

- HTTPS

- identify

- Impact

- importance

- important

- in

- Including

- increasingly

- individual

- information

- instance

- interesting

- International

- ISO

- IT

- join

- Know

- Knowing

- labeling

- Labels

- language

- Last

- Late

- launching

- lead

- likely

- List

- Look

- LOOKS

- made

- maintain

- make

- manager

- managing

- manufacturing

- many

- mark

- Market

- material

- materials

- max-width

- meaning

- medical

- medical device

- method

- methods

- Meyer

- more

- Need

- New

- North

- north america

- Offers

- ONE

- order

- organization

- original

- Other

- overview

- paperwork

- parts

- permanent

- perspectives

- Peter

- plato

- Plato Data Intelligence

- PlatoData

- player

- Popular

- process

- processing

- Product

- product development

- Products

- Program

- Programs

- PROS

- provides

- purchase

- purchase order

- quality

- reach

- reason

- regulations

- released

- reliability

- requires

- restriction

- sections

- secure

- selecting

- selection

- serve

- several

- Share

- Sight

- Signal

- Simple

- simplified

- smoother

- solution

- some

- specification

- Stage

- stages

- standards

- Starfish

- Study

- substantial

- sufficient

- SUMMARY

- supply

- supply chain

- Systems

- Target

- team

- teamwork

- techniques

- terminology

- Testing

- The

- the world

- their

- three

- Through

- time

- to

- top

- Top 10

- Topics

- unit

- Universal

- Update

- updated

- use

- usually

- value

- variety

- Vast

- vendor

- vendors

- Video

- well-defined

- What

- which

- will

- Won

- world

- Your

- youtube

- zephyrnet