Inventory is often the single largest asset in most companies across any industry. It consumes a lot of cash, impacts return on investment and profitability, enables or impedes growth and customer satisfaction, and requires a tremendous amount of resource to manage it. Inventory Management is critical.

Paljud suured ja väikesed, hästi tuntud ja idufirmad näevad aga vaeva, et laoseisu tõhusalt hallata.

Selles "Lisaks” series article we are putting the spotlight on Inventory Management. We are presenting our Top 10 Inventory Management articles with techniques and approaches which will have something for everyone to learn from and apply in their own situation.

1. Laovarude käibe läbimurre … Mine tagasi põhitõdede juurde!

Mind üllatavad alati inimesed, kes usuvad, et varude käibe parandamiseks on vaja väga keerulisi süsteeme ja protsesse.

In our experience it is most important to go back to the basics. Think about the very basic business processes that are involved in Inventory Management: which processes control the rate at which you move inventory into your business, through your business, and out of your business.

Keep it simple! We’ve achieved industry leading results using this approach.

2. Do You Want Inventory Turnover Breakthrough? Define and Manage the Levers!

Seoses meie artikliga „Tagasiminek põhitõdede juurde” on oluline kaardistada meie kõige mõjukamad protsessid, mis kontrollivad varude voogu teie ettevõttesse, läbi ja sealt välja.

Pick a few key business processes defined that will have the greatest impact on Inventory turnover and choose to improve those specifically. Often people either pick only one business process to improve or they pick far too many processes to improve.

Kui olete määratlenud selle piiratud arvu suure võimendusega protsesse, on teil hallatav ulatus laohalduses suurima mõju saavutamiseks.

3. Topeltkäive 9 kuuga!

I joined a Supply Chain services company that had logistics and distribution as its core offering. Much to my surprise the inventory turnover level was only around 7 times a year, which is not very impressive if you are telling your customers how great you are at Supply Chain.

Kasutades põhimõtteid ja lähenemisviise, mida oleme arutanud teistes artiklites, kavatseme parandada Inventory Management protsessid ja tulemused.

Within 9 months we had doubled the Inventory turnover in the company moving it from being an industry laggard to being an industry leaders. Read about our journey and how we achieved these results.

4. Achieve Breakthrough Results! Go From Worst to First!

The company had perennial had the worst Inventory turnover performance in the Industry. But the Board had enough and charged my Boss with getting this back in line quickly.

My Boss asked me to step in and take on this challenge. I had seen a lot of my predecessors try this and fail. So I needed to take a different approach.

Kasutades tehnikaid ja lähenemisviise, mida oleme mujal arutanud, alustasime seda teekonda, mille tulemusel asus ettevõte varude käibe osas tööstusharu juhtima vaid 9 kuud pärast projekti alustamist.

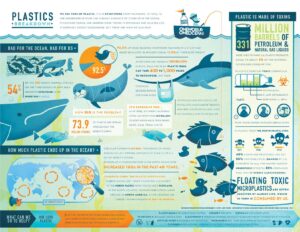

5. World Class Inventory Turnover Breakthrough Elements! (Infographic)

There are many different approaches that people take to tackle Inventory Management. Based on our experiences we felt that it was important to share the elements of effective Inventory Management approaches that we’ve used to great effect.

We captured this approach in an Infographic. As with anything it is a reflection of our successes, failures and learnings across many organizations, industries, cultures and geographies.

6. Part Shortages? What is Your Supply Line Strategy?

Stereotüüpne laohalduse dilemma seisneb selles, et teil on liiga palju valesid osi ja liiga vähe õigeid osi.

In particular Part Shortages can bring your company to its knees. Shortages will stop your manufacturing lines, impede your retail and online sales, and cost you customers, profit and business growth.

Materjalipuuduse haldamise strateegia abil saate nende probleemide mõju ära hoida või leevendada ning säilitada teie võimet juhtida erakordset varude jõudlust.

7. Kõrge hinnaga ekspediitori ülestunnistused!

A key element of any part shortage mitigation strategy has to be having a Supply Line recovery process. Anyone in Supply Chain knows that this means having resources and processes for the expediting the supply of parts.

Olles kulutanud palju aega ja energiat osade puuduse kiirendamisele, tundsime, et kõige õigem on neid kogemusi kõigi hüvanguks jagada.

Kiire, tõhus ja tõhus osade puuduse kiirendamine viib teie varude haldamise plaanid tagasi õigele teele ja minimaalse mõjuga.

8. 4 väljakutset SIOP (S&OP) äriprotsessi käivitamisel ja säilitamisel!

Tõhusa varude haldamise üks peamisi aspekte on väga integreeritud SIOP (müügi, laoseisu ja operatsioonide planeerimine) või S&OP äriprotsess.

If you don’t have a SIOP business process in place you will face many obstacles and hurdles in getting it started. And even if you have a SIOP business process that is being used it can be just as difficult in keeping it going.

Meie artikkel räägib väga tõelistest väljakutsetest, mida peate oma teekonnal mitte ainult laoseisu, vaid kogu äritegevuse haldamisel ära tundma ja ületama.

9. Leani kasutamine varude haldamiseks

Most of use have heard of, if not been involved in, Lean process improvement programs. Typically associated with improving manufacturing processes Lean is also applicable for Inventory Management.

See Veridiani külalisartikkel on suurepärane arutelu selle üle, kuidas kasutada varude haldamiseks Lean-programmi.

10. Solving the Out of Stock Problem! (Infographic)

Having worked in Retail I know how quickly everyone gets upset, from the CEO on down, when a store is out of stock of a particular item. While forecasting, fulfillment and replenishment are not exact sciences there is often no to little understanding of this complexity outside of Supply Chain.

See 2flow teabegraafik käsitleb meetmeid, mida võtta, et vähendada varude vähenemist teie jaemüügi- ja muudes keskkondades.

Autoriõigus © Mortson Enterprises Inc. Kõik õigused kaitstud.

Algselt avaldati 13. augustil 2019.

- SEO-põhise sisu ja PR-levi. Võimenduge juba täna.

- PlatoData.Network Vertikaalne generatiivne Ai. Jõustage ennast. Juurdepääs siia.

- PlatoAiStream. Web3 luure. Täiustatud teadmised. Juurdepääs siia.

- PlatoESG. Süsinik, CleanTech, Energia, Keskkond päikeseenergia, Jäätmekäitluse. Juurdepääs siia.

- PlatoTervis. Biotehnoloogia ja kliiniliste uuringute luureandmed. Juurdepääs siia.

- Allikas: https://supplychaingamechanger.com/featuring-our-top-10-inventory-management-articles/

- :on

- :on

- :mitte

- 10

- 13

- 2019

- 7

- 9

- a

- võime

- MEIST

- saavutada

- üle

- pärast

- Materjal: BPA ja flataatide vaba plastik

- Ka

- alati

- am

- summa

- an

- ja

- mistahes

- keegi

- midagi

- kohaldatav

- kehtima

- lähenemine

- lähenemisviisid

- asjakohane

- OLEME

- ümber

- artikkel

- kaubad

- AS

- aspektid

- eelis

- seotud

- At

- AUGUST

- tagasi

- tagasi õigele teele

- põhineb

- põhiline

- Alused

- BE

- olnud

- hakkas

- on

- Uskuma

- kasu

- BEST

- Suur

- juhatus

- BOSS

- läbimurre

- tooma

- äri

- Äriprotsess

- äriprotsessid

- kuid

- by

- CAN

- pildistatud

- Raha

- tegevjuht

- kett

- väljakutse

- väljakutseid

- laetud

- Vali

- klass

- Ettevõtted

- ettevõte

- keerukus

- keeruline

- koos

- kontrollida

- tuum

- Maksma

- kriitiline

- klient

- Kliendi rahulolu

- Kliendid

- määratlema

- määratletud

- erinev

- raske

- arutatud

- arutelu

- jaotus

- do

- Ära

- kahekordistunud

- alla

- ajam

- mõju

- Tõhus

- tõhusalt

- tõhus

- kumbki

- element

- elemendid

- mujal

- võimaldab

- energia

- piisavalt

- ettevõtete

- Kogu

- keskkondades

- Isegi

- igaüks

- erandlik

- kogemus

- Kogemused

- nägu

- FAIL

- rikete

- kaugele

- Lisaks

- viga

- vähe

- voog

- eest

- Alates

- täitmine

- mäng

- geograafiad

- saama

- saamine

- Go

- läheb

- suur

- suurim

- Kasv

- külaline

- Külalisartikkel

- olnud

- Olema

- võttes

- kuulnud

- Suur

- kõrgelt

- Kuidas

- Kuidas

- HTTPS

- Takistused

- i

- if

- mõju

- mõjuv

- Mõjud

- oluline

- muljetavaldav

- parandama

- paranemine

- parandusi

- Paranemist

- in

- Teistes

- Inc

- tööstusharudes

- tööstus

- Infographic

- integreeritud

- sisse

- inventar

- Inventory Management

- investeering

- seotud

- küsimustes

- IT

- ITS

- liitunud

- teekond

- jpg

- lihtsalt

- pidamine

- Võti

- Teadma

- teatud

- teab

- suurim

- juhid

- juhtivate

- Õppida

- Tase

- Finantsvõimendus

- piiratud

- joon

- liinid

- vähe

- logistika

- Partii

- juhtima

- juhtimine

- juhtiv

- tootmine

- palju

- kaart

- materjal

- me

- vahendid

- meetmed

- minimaalne

- leevendav

- leevendamine

- kuu

- kõige

- liikuma

- liikuv

- palju

- peab

- my

- Vajadus

- vaja

- Uus

- ei

- number

- takistusi

- of

- pakkumine

- sageli

- on

- ONE

- Internetis

- veebimüük

- ainult

- OP

- Avaneb

- töö

- Operations

- or

- et

- organisatsioonid

- Muu

- meie

- välja

- väljaspool

- Ületada

- enda

- osa

- eriline

- osad

- Inimesed

- jõudlus

- valima

- Koht

- planeerimine

- plaanid

- Platon

- Platoni andmete intelligentsus

- PlatoData

- säilitamine

- ennetada

- põhimõtted

- protsess

- Protsessid

- Kasum

- kasumlikkus

- Programm

- Programmid

- projekt

- avaldatud

- Putting

- kiiresti

- määr

- Lugenud

- reaalne

- tunnustatud

- taastumine

- vähendama

- peegeldus

- Vajab

- reserveeritud

- ressurss

- Vahendid

- põhjustanud

- Tulemused

- jaemüük

- tagasipöördumine

- õige

- õigusi

- müük

- rahulolu

- TEADUSED

- ulatus

- nähtud

- Seeria

- Teenused

- teenindusettevõte

- komplekt

- Jaga

- puudus

- puudus

- ühekordne

- olukord

- väike

- So

- midagi

- keeruline

- eriti

- kasutatud

- prožektor

- alustatud

- Käivitus

- Alustavatel

- Samm

- varu

- Peatus

- salvestada

- Strateegia

- võitlus

- edu

- varustama

- tarneahelas

- üllatus

- üllatunud

- süsteemid

- lahendada

- Võtma

- Läbirääkimised

- tehnikat

- paljuütlev

- et

- .

- Põhitõed

- oma

- Seal.

- Need

- nad

- mõtlema

- see

- need

- Läbi

- aeg

- korda

- et

- liiga

- ülemine

- Top 10

- jälgida

- tohutu

- püüdma

- käive

- tüüpiliselt

- mõistmine

- kasutama

- Kasutatud

- kasutamine

- väga

- tahan

- oli

- we

- Hästi

- M

- Mis on

- millal

- mis

- kuigi

- WHO

- will

- koos

- töötas

- halvim

- Vale

- aasta

- sa

- Sinu

- sephyrnet