Inventory is often the single largest asset in most companies across any industry. It consumes a lot of cash, impacts return on investment and profitability, enables or impedes growth and customer satisfaction, and requires a tremendous amount of resource to manage it. Inventory Management is critical.

Mesmo assim, muitas empresas, grandes e pequenas, bem conhecidas e iniciantes, lutam para gerenciar o estoque de maneira eficaz.

Nisso "Apresentando” series article we are putting the spotlight on Inventory Management. We are presenting our Top 10 Inventory Management articles with techniques and approaches which will have something for everyone to learn from and apply in their own situation.

1. Avanço no giro de estoque… Volte ao básico!

Sempre fico surpreso com as pessoas que acreditam que são necessários sistemas e processos altamente sofisticados e complicados para impulsionar melhorias no giro de estoque.

In our experience it is most important to go back to the basics. Think about the very basic business processes that are involved in Inventory Management: which processes control the rate at which you move inventory into your business, through your business, and out of your business.

Keep it simple! We’ve achieved industry leading results using this approach.

2. Do You Want Inventory Turnover Breakthrough? Define and Manage the Levers!

Em conjunto com nosso artigo sobre “Voltando ao Básico”, é importante mapear nossos processos mais impactantes que controlam a taxa de fluxo de estoque para dentro, através e fora de seu negócio.

Pick a few key business processes defined that will have the greatest impact on Inventory turnover and choose to improve those specifically. Often people either pick only one business process to improve or they pick far too many processes to improve.

Depois de definir esse número limitado de processos de alta alavancagem, você terá um escopo gerenciável para gerar o maior impacto no gerenciamento de estoque.

3. Rotatividade de estoque dobrada em 9 meses!

I joined a Supply Chain services company that had logistics and distribution as its core offering. Much to my surprise the inventory turnover level was only around 7 times a year, which is not very impressive if you are telling your customers how great you are at Supply Chain.

Usando os princípios e abordagens que discutimos em outros artigos, pretendemos melhorar o Gestão de Inventário processos e resultados.

Within 9 months we had doubled the Inventory turnover in the company moving it from being an industry laggard to being an industry leaders. Read about our journey and how we achieved these results.

4. Achieve Breakthrough Results! Go From Worst to First!

The company had perennial had the worst Inventory turnover performance in the Industry. But the Board had enough and charged my Boss with getting this back in line quickly.

My Boss asked me to step in and take on this challenge. I had seen a lot of my predecessors try this and fail. So I needed to take a different approach.

Usando as técnicas e abordagens que discutimos em outro lugar, iniciamos esta jornada que resultou na empresa líder do setor em giro de estoque apenas 9 meses após iniciarmos o projeto.

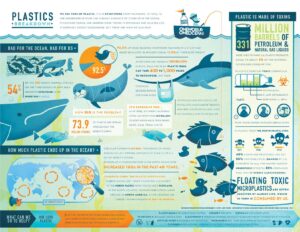

5. World Class Inventory Turnover Breakthrough Elements! (Infographic)

There are many different approaches that people take to tackle Inventory Management. Based on our experiences we felt that it was important to share the elements of effective Inventory Management approaches that we’ve used to great effect.

We captured this approach in an Infographic. As with anything it is a reflection of our successes, failures and learnings across many organizations, industries, cultures and geographies.

6. Part Shortages? What is Your Supply Line Strategy?

O dilema estereotipado do gerenciamento de estoque é que você tem muitas peças erradas e poucas peças certas.

In particular Part Shortages can bring your company to its knees. Shortages will stop your manufacturing lines, impede your retail and online sales, and cost you customers, profit and business growth.

Ter uma estratégia para gerenciar a escassez de materiais fará maravilhas para prevenir ou mitigar o impacto desses problemas e preservar sua capacidade de gerar um desempenho excepcional de estoque.

7. Confissões de um Expedidor de Alto Preço!

A key element of any part shortage mitigation strategy has to be having a Supply Line recovery process. Anyone in Supply Chain knows that this means having resources and processes for the expediting the supply of parts.

Tendo gasto muito tempo e energia para agilizar a escassez de peças, sentimos que era mais apropriado compartilhar essas experiências para o benefício de todos.

A expedição rápida, eficiente e eficaz da escassez de peças colocará seus planos de gerenciamento de estoque de volta nos trilhos com impacto mínimo.

8. 4 Desafios para iniciar e sustentar um processo de negócios SIOP (S&OP)!

Um dos principais aspectos do gerenciamento de estoque eficaz é ter um processo de negócios SIOP (Planejamento de vendas, estoque e operações) altamente integrado, ou S&OP.

If you don’t have a SIOP business process in place you will face many obstacles and hurdles in getting it started. And even if you have a SIOP business process that is being used it can be just as difficult in keeping it going.

Nosso artigo fala sobre os desafios reais que você deve reconhecer e superar em sua jornada para gerenciar não apenas o estoque, mas toda a operação do seu negócio.

9. Usando Lean para gerenciar estoque

Most of use have heard of, if not been involved in, Lean process improvement programs. Typically associated with improving manufacturing processes Lean is also applicable for Inventory Management.

Este artigo convidado da Veridian é uma ótima discussão sobre como usar um programa Lean para gerenciar estoque.

10. Solving the Out of Stock Problem! (Infographic)

Having worked in Retail I know how quickly everyone gets upset, from the CEO on down, when a store is out of stock of a particular item. While forecasting, fulfillment and replenishment are not exact sciences there is often no to little understanding of this complexity outside of Supply Chain.

Este infográfico da 2flow discute medidas a serem tomadas para reduzir rupturas de estoque em seu varejo e outros ambientes.

Copyright © Mortson Enterprises Inc. Todos os direitos reservados.

Publicado originalmente em 13 de agosto de 2019.

- Conteúdo com tecnologia de SEO e distribuição de relações públicas. Seja amplificado hoje.

- PlatoData.Network Gerativa Vertical Ai. Capacite-se. Acesse aqui.

- PlatoAiStream. Inteligência Web3. Conhecimento Amplificado. Acesse aqui.

- PlatãoESG. Carbono Tecnologia Limpa, Energia, Ambiente, Solar, Gestão de resíduos. Acesse aqui.

- PlatoHealth. Inteligência em Biotecnologia e Ensaios Clínicos. Acesse aqui.

- Fonte: https://supplychaingamechanger.com/featuring-our-top-10-inventory-management-articles/

- :tem

- :é

- :não

- 10

- 13

- 2019

- 7

- 9

- a

- habilidade

- Sobre

- alcançado

- em

- Depois de

- Todos os Produtos

- tb

- sempre

- am

- quantidade

- an

- e

- qualquer

- qualquer um

- nada

- relevante

- Aplicar

- abordagem

- se aproxima

- apropriado

- SOMOS

- por aí

- artigo

- artigos

- AS

- aspectos

- ativo

- associado

- At

- AGOSTO

- em caminho duplo

- de volta à pista

- baseado

- basic

- fundamentos básicos

- BE

- sido

- começou

- ser

- Acreditar

- beneficiar

- MELHOR

- Grande

- borda

- CHEFE

- avanço

- trazer

- negócio

- Processo de negócio

- processos de negócios

- mas a

- by

- CAN

- capturados

- dinheiro

- Chefe executivo

- cadeia

- desafiar

- desafios

- carregada

- Escolha

- classe

- Empresas

- Empresa

- complexidade

- complicado

- conjunção

- ao controle

- núcleo

- Custo

- crítico

- cliente

- A satisfação do cliente

- Clientes

- definir

- definido

- diferente

- difícil

- discutido

- discussão

- distribuição

- do

- não

- duplicou

- down

- distância

- efeito

- Eficaz

- efetivamente

- eficiente

- ou

- elemento

- elementos

- em outro lugar

- permite

- energia

- suficiente

- empresas

- Todo

- ambientes

- Mesmo

- todos

- excepcional

- vasta experiência

- Experiências

- Rosto

- FALHA

- falhas

- longe

- Apresentando

- erro

- poucos

- fluxo

- Escolha

- da

- cumprimento

- jogo

- geografias

- ter

- obtendo

- Go

- vai

- ótimo

- maior

- Growth

- Locatário

- Artigo convidado

- tinha

- Ter

- ter

- ouviu

- Alta

- altamente

- Como funciona o dobrador de carta de canal

- Como Negociar

- HTTPS

- Obstáculos

- i

- if

- Impacto

- impactante

- Impacto

- importante

- impressionante

- melhorar

- melhoria

- melhorias

- melhorar

- in

- Em outra

- Inc.

- indústrias

- indústria

- infográfico

- integrado

- para dentro

- inventário

- Gestão de Inventário

- investimento

- envolvido

- questões

- IT

- ESTÁ

- ingressou

- viagem

- jpg

- apenas por

- manutenção

- Chave

- Saber

- conhecido

- sabe

- maior

- líderes

- principal

- APRENDER

- Nível

- Alavancagem

- Limitado

- Line

- linhas

- pequeno

- logística

- lote

- gerencia

- de grupos

- gestão

- fabrica

- muitos

- mapa,

- material

- me

- significa

- medidas

- mínimo

- mitigando

- mitigação

- mês

- a maioria

- mover

- em movimento

- muito

- devo

- my

- você merece...

- necessário

- Novo

- não

- número

- obstáculos

- of

- oferecendo treinamento para distância

- frequentemente

- on

- ONE

- online

- Vendas online

- só

- OP

- abre

- operação

- Operações

- or

- ordem

- organizações

- Outros

- A Nossa

- Fora

- lado de fora

- Superar

- próprio

- parte

- particular

- peças

- Pessoas

- atuação

- escolher

- Lugar

- planejamento

- planos

- platão

- Inteligência de Dados Platão

- PlatãoData

- preservando

- impedindo

- princípios

- processo

- processos

- Lucro

- rentabilidade

- Agenda

- Programas

- projeto

- publicado

- Colocar

- rapidamente

- Taxa

- Leia

- reais

- reconhecido

- recuperação

- reduzir

- reflexão

- exige

- reservado

- recurso

- Recursos

- resultou

- Resultados

- varejo

- retorno

- certo

- direitos

- vendas

- satisfação

- CIÊNCIAS

- escopo

- visto

- Série

- Serviços

- empresa de serviços

- conjunto

- Partilhar

- escassez

- escassez

- solteiro

- situação

- pequeno

- So

- algo

- sofisticado

- especificamente

- gasto

- Holofote

- começado

- Comece

- Startups

- Passo

- estoque

- Dê um basta

- loja

- Estratégia

- Lutar

- sucessos

- supply

- cadeia de suprimentos

- surpresa

- admirado

- sistemas

- equipamento

- Tire

- negociações

- técnicas

- dizendo

- que

- A

- O Básico

- deles

- Lá.

- Este

- deles

- think

- isto

- aqueles

- Através da

- tempo

- vezes

- para

- também

- topo

- 10 topo

- pista

- tremendo

- tentar

- volume de negócios

- tipicamente

- compreensão

- usar

- usava

- utilização

- muito

- queremos

- foi

- we

- BEM

- O Quê

- O que é a

- quando

- qual

- enquanto

- QUEM

- precisarão

- de

- trabalhou

- o pior

- Errado

- ano

- Você

- investimentos

- zefirnet