Enhanced vision capabilities, with the use of smart glasses, provide warehousing workers and operations with simplicity, efficiency and accuracy that systems based on voice, radio frequency, or paper just can’t. Here are five reasons for companies to consider providing these advanced capabilities to their warehousing workers and systems.

Enhanced vision capabilities provide augmented reality, not virtual reality.

Virtual reality replaces existing reality with a digital alternative. That may be good for some training applications, but it’s not what you want for workers operating dangerous equipment and moving physical goods.

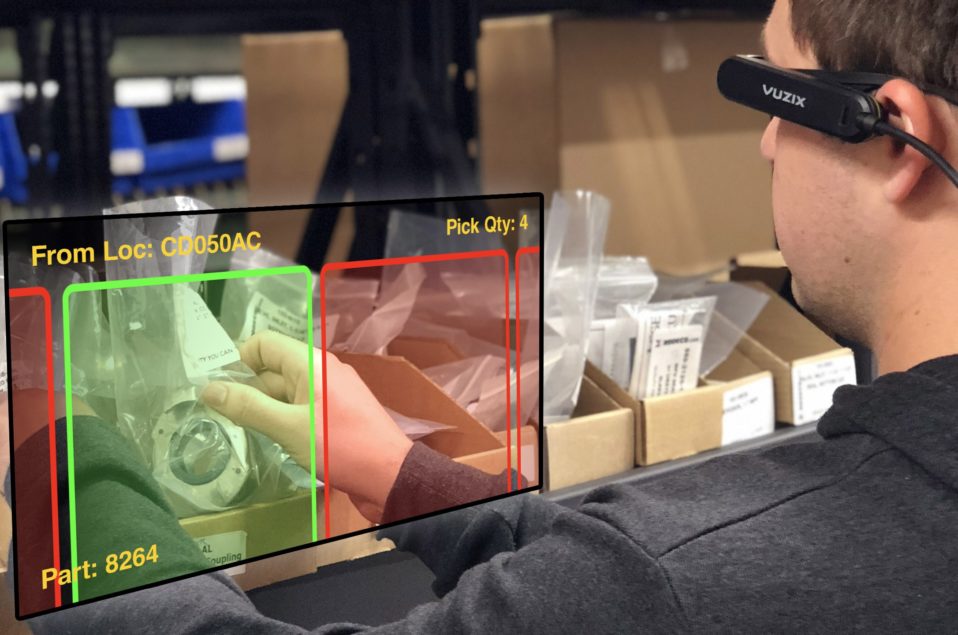

Augmented reality uses sensors and other digital means to overlay information within smart glasses to provide context to the warehouse environment. For example, cameras built into smart glasses read barcodes and QR codes, or absorb information with optical character recognition (OCR), to pinpoint the location of a picker within a facility and provide a signal within the glasses to indicate where the worker is to pick from. Providing greater certainty and clarity increases workers’ efficiency and enhances their safety because they aren’t distracted by looking at a handheld screen or a paper document.

Smart glasses are user-friendly.

Smart glasses provide interaction among warehouse environments, workers and backend systems. The data that the systems provide to help warehouse workers do their jobs better is displayed within the glasses.

Smart glasses require a short adjustment period for those who have never worn a pair before. Workers often have questions when they’re first introduced to the devices, but experience has shown that a quick training program on how to wear and use them properly provides workers with a high level of proficiency within 10 to 15 minutes, and that they are then able to wear the smart glasses comfortably all day.

Smart glasses are lightweight and designed to distribute weight evenly, and they can be worn with corrective lenses. The devices are adjustable to accommodate each worker’s dominant eye. Like the information drivers view on their car dashboards, workers quickly glance at the data being displayed without losing focus on the task at hand.

Enhanced vision technology helps warehousing workforces.

One of the biggest complaints heard today among warehouse workers concerns the complexity of the systems they’re using. These systems often require substantial training to gain proficiency, and the work involves absorbing complex information displayed on a screen. The biggest benefit that enhanced vision provides to warehousing workers is that it simplifies their tasks.

Enhanced vision capabilities simplify instructions for workers, by providing visual instructions such as green and red signals, so that there’s as little text involved as possible. Green for “Go” and red for “Stop” are intuitive and universally understood instructions, making end users’ jobs easier and allowing them to perform tasks more effectively and efficiently.

Heads-up displays like smart glasses provide workers with instructions in their line of sight, making the instructions easier for workers to process and freeing their hands to perform manual tasks. Visual instructions, which are always in front of workers’ eyes, are superior to voice instructions that have to be memorized and may have to be repeated.

Smart glasses provide information and instructions to individual workers. In the case of a pick-to-light system, two workers standing next to each other have no way of knowing for whom a specific light signal is intended. Visual instructions are sent to individual workers within their smart glasses and appear right in front of each worker’s eyes, which facilitates efficient work processes.

Enhanced vision allows companies to scrap paper systems and complements RF and voice.

The business world is changing and increasing in complexity, requiring more data collection and visibility. Some companies have found it difficult to commit to implementing technologies that help manage complexity. Warehouses that still operate in a paper world are behind the eight-ball at this point.

Companies that have invested in radio-frequency technologies and voice instruction for their warehouses are in better shape but can do better. RF devices occupy workers’ hands and divert their attention to receive data and instructions. Their eyes are focused on their devices instead of on their jobs.

Voice instructions are conveyed through a headset, but there's a limit to the complexity that workers can capture with their hearing and what they can remember. A 20-digit identifier, for example, would be much better captured with the sense of sight.

Vision capabilities put displays directly in line with the work being done so that it’s accomplished more quickly and with greater accuracy. Today’s vision systems allow voice instructions to complement visual instructions if that helps operations.

State-of-the-art vision systems are more cost-effective than their historical predecessors, relying on newer technologies that are less expensive. The latest technology doesn’t require overhauling and rebuilding existing systems. So companies can now consider scrapping their paper systems or investing in a technology refresh without breaking the bank.

New vision technology works with a company’s current enterprise systems.

Vision software takes data from WMS and ERP systems and converts it into instructions for humans and robots in the warehouse. The system accomplishes this feat without a great deal of time-consuming and costly systems integration.

Advances in data science provide options for establishing data connectivity among enterprise systems. Data languages used by various WMS and ERP apps vary, and today’s advanced vision systems build in standard capabilities that enable the vision system to handle data from those other enterprise systems. Self-service workflow engines in advanced vision systems allow users to design and control operational processes without writing any software code, providing a flexible and cost-effective solution.

LogistiVIEW—Using Vision to Make the Warehouse Picking Process More Efficient

LogistiVIEW is a workforce optimization solution that delivers a vision-driven experience for warehouse workers. “Unlike traditional handheld or voice technologies,” explains Seth Patin, the company’s CEO, “our Vision+ solution uses smart glasses to provide a visual display. The smart glasses interact with a LogistiVIEW platform server, which acts as a hub for all connectivity and digital messaging inside the warehouse.” The system can also connect workers with work instructions in other ways, such as voice guidance, if required.

LogistiVIEW is built around a workflow engine that enables tailored solutions for individual warehouse processes. “The system very quickly gathers and processes information,” says David Erickson, LogistiVIEW’s chief technology officer. “We’re able to capture images and videos and integrate them much more dynamically with how workers perform their jobs.”

LogistiVIEW’s solution can integrate with legacy enterprise systems without making significant changes to them. “Several of our techniques and some of our patented intellectual property allow users to do that integration with minimal or non-existent changes to the backend,” says Erickson. “We developed a drag-and-drop approach to developing workflows and a creative data-mapping engine that provides data translations without ever going into code.”

All of these innovations benefit LogistiVIEW’s customers. The solution has been documented to increase picking accuracy by 20%, and costs up to 80% less than pick-to-light systems and around 50% less than voice systems.

LogistiVIEW, says Patin, “makes the warehouse picking process tangibly more efficient.”

Resource Link: www.logistiview.com

- SEO Powered Content & PR Distribution. Get Amplified Today.

- Platoblockchain. Web3 Metaverse Intelligence. Knowledge Amplified. Access Here.

- Source: https://www.supplychainbrain.com/articles/36111-five-reasons-to-invest-in-enhanced-vision-technology-for-your-warehouse

- 10

- a

- Able

- accommodate

- accomplished

- accuracy

- acts

- adjustable

- Adjustment

- advanced

- All

- Allowing

- allows

- alternative

- always

- among

- and

- appear

- applications

- approach

- apps

- around

- attention

- augmented

- Augmented Reality

- Backend

- Bank

- based

- because

- before

- behind

- being

- benefit

- Better

- Biggest

- Breaking

- build

- built

- business

- cameras

- capabilities

- capture

- car

- case

- ceo

- certainty

- Changes

- changing

- character

- character recognition

- chief

- chief technology officer

- clarity

- code

- collection

- COM

- commit

- Companies

- Company’s

- complaints

- Complement

- complex

- complexity

- Concerns

- Connect

- Connectivity

- Consider

- context

- control

- cost-effective

- Costs

- Creative

- Current

- Customers

- Dangerous

- data

- data science

- David

- day

- deal

- delivers

- Design

- designed

- developed

- developing

- Devices

- difficult

- digital

- directly

- Display

- displays

- distribute

- document

- Doesn’t

- dominant

- drivers

- each

- easier

- effectively

- efficiency

- efficient

- efficiently

- enable

- enables

- Engine

- Engines

- enhanced

- Enhances

- Enterprise

- Environment

- environments

- equipment

- ERP

- establishing

- EVER

- example

- existing

- expensive

- experience

- Explains

- eye

- Eyes

- facilitates

- Facility

- feat

- File

- First

- flexible

- Focus

- focused

- found

- Frequency

- from

- front

- Gain

- Glance

- glasses

- going

- good

- goods

- great

- greater

- Green

- handle

- Hands

- Headset

- heard

- hearing

- help

- helps

- here

- High

- historical

- How

- How To

- HTTPS

- Hub

- Humans

- identifier

- images

- implementing

- in

- In other

- Increase

- Increases

- increasing

- indicate

- individual

- information

- innovations

- instead

- instructions

- integrate

- integration

- intellectual

- intellectual property

- interact

- interaction

- introduced

- intuitive

- Invest

- invested

- investing

- involved

- IT

- Jobs

- Knowing

- Languages

- latest

- Legacy

- lenses

- Level

- light

- lightweight

- LIMIT

- Line

- LINK

- little

- location

- looking

- losing

- make

- Making

- manage

- manual

- means

- messaging

- minimal

- minutes

- more

- more efficient

- moving

- New

- next

- OCR

- Officer

- operate

- operating

- operational

- Operations

- optical character recognition

- optimization

- Options

- Other

- Paper

- patented

- perform

- period

- physical

- pick

- platform

- plato

- Plato Data Intelligence

- PlatoData

- Point

- possible

- process

- processes

- Program

- properly

- property

- provide

- provides

- providing

- put

- qr-codes

- Questions

- Quick

- quickly

- Radio

- Read

- Reality

- reasons

- receive

- recognition

- Red

- remember

- repeated

- require

- required

- robots

- Safety

- Science

- Screen

- Self-service

- sense

- sensors

- Shape

- Short

- shown

- Sight

- Signal

- signals

- significant

- simplicity

- simplify

- smart

- Smart glasses

- So

- Software

- solution

- Solutions

- some

- specific

- standard

- Still

- substantial

- such

- superior

- system

- Systems

- tailored

- takes

- Task

- tasks

- techniques

- Technologies

- Technology

- The

- the information

- their

- Through

- time-consuming

- to

- today

- today’s

- traditional

- Training

- Translations

- understood

- use

- user-friendly

- users

- various

- Videos

- View

- Virtual

- Virtual reality

- visibility

- vision

- vision systems

- Voice

- Warehouse

- Warehousing

- ways

- weight

- What

- which

- WHO

- within

- without

- WMS

- Work

- worker

- workers

- workflow

- workflows

- Workforce

- works

- world

- would

- writing

- Your

- zephyrnet