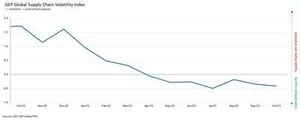

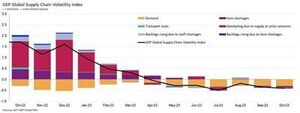

The GEP Global Supply Chain Volatility Index — the indicator tracking demand conditions, shortages, transportation costs, inventories and backlogs based on a monthly survey of 27,000 businesses — decreased again in October to -0.41, from -0.35 in September, indicating a 7th successive month of rising spare capacity across the world’s supply chains.

Additionally, the extent to which supplier capacity went underutilised was even greater than in September and August. Coupled with October’s downturn in demand for raw materials, components and commodities, this shows rising slack in global supply chains.

“While the shrinking of global suppliers’ order books is not worsening, there are no signs of improvement,” explained Jamie Ogilvie-Smals, vice president, consulting, GEP. “The notable increase in supplier capacity in Asia, which was driven by China, provides global manufacturers with greater leverage to drive down prices and inventories in 2024.”

A key finding from October’s report was the strongest rise in excess capacity across Asian supply chains since June 2020. Sustained weakness in demand, coupled with falling pressures on factories in Asia, indicates that the global manufacturing recession has further to run. With the exception of India, which continues to perform strongly, large economies in the region, such as Japan and China, are losing momentum.

Suppliers in Europe continue to report the largest level of spare capacity. In fact, the lower levels in GEP’s supply chain index for the continent have only been seen during the global financial crisis between 2008 and 2009. They highlight sustained weakness in economic conditions across the continent. Western Europe, particularly Germany’s manufacturing industry, is a key driver behind the region’s deterioration.

Un punto relativamente positivo è il Nord America, dove le catene di approvvigionamento hanno una capacità in eccesso, ma in misura molto minore che altrove, poiché l’economia statunitense continua a mostrare la sua resilienza, in netto contrasto con l’Europa.

Ottobre 2023 Principali risultati

Demand: Demand for raw materials, components and commodities remains depressed, although the downturn seems to have stabilised. There are still no signs of conditions improving, however, as global purchasing activity fell again in October at a pace similar to what we’ve seen since around mid-year.

Demand: Demand for raw materials, components and commodities remains depressed, although the downturn seems to have stabilised. There are still no signs of conditions improving, however, as global purchasing activity fell again in October at a pace similar to what we’ve seen since around mid-year.- Scorte: con la domanda in calo, i nostri dati mostrano un altro mese di riduzione delle scorte da parte delle aziende globali, segnalando gli sforzi di conservazione del flusso di cassa.

- Carenza di materiali: le segnalazioni di carenze di articoli rimangono al livello più basso da gennaio 2020.

- Labour shortages: Shortages of workers are not impacting global manufacturers’ capacity to produce, with reports of backlogs due to inadequate labour supply running at historically typical levels.

- Transportation: Global transportation costs held steady with September’s level, although oil prices have declined in recent weeks.

Volatilità della catena di fornitura regionale

-

Nord America: l'indice è sceso a -0.34, da -0.30. Questo rimane molto più debole rispetto alla media globale e continua a suggerire il caso degli Stati Uniti. l’economia è pronta per un atterraggio morbido.

- Europa: l'indice è salito a -0.90, da -1.01, ma rimane ancora a un livello indicativo di notevole fragilità economica.

- Regno Unito: L'indice è leggermente salito a -0.93, da -0.98. Tuttavia, i dati indicano un aumento sostanziale della capacità in eccesso presso i fornitori dei mercati del Regno Unito.

- Asia: Notably, the index dropped to -0.38, from -0.20, highlighting the biggest rise in spare supplier capacity in Asia since June 2020 as the region’s resilience fades.

- Distribuzione di contenuti basati su SEO e PR. Ricevi amplificazione oggi.

- PlatoData.Network Generativo verticale Ai. Potenzia te stesso. Accedi qui.

- PlatoAiStream. Intelligenza Web3. Conoscenza amplificata. Accedi qui.

- PlatoneESG. Carbonio, Tecnologia pulita, Energia, Ambiente, Solare, Gestione dei rifiuti. Accedi qui.

- Platone Salute. Intelligence sulle biotecnologie e sulle sperimentazioni cliniche. Accedi qui.

- Fonte: https://www.logisticsit.com/articles/2023/11/21/supply-chains-worldwide-remain-significantly-underutilised-gep-global-supply-chain-volatility-index

- :ha

- :È

- :non

- :Dove

- 000

- 01

- 121

- 20

- 2008

- 2020

- 2023

- 2024

- 27

- 30

- 300

- 35%

- 41

- 7°

- 90

- 98

- a

- operanti in

- attività

- ancora

- Sebbene il

- America

- ed

- Un altro

- SONO

- in giro

- AS

- Asia

- asiatico

- At

- AGOSTO

- media

- basato

- stato

- dietro

- fra

- Maggiore

- Libri

- Brillants

- aziende

- ma

- by

- Ultra-Grande

- catena

- Catene

- Cina

- Materie prime

- componenti

- condizioni

- notevole

- consulting

- continente

- continua

- continua

- contrasto

- Costi

- accoppiato

- crisi

- dati

- diminuita

- Richiesta

- Dsiplay

- giù

- DISCESA

- guidare

- spinto

- autista

- caduto

- dovuto

- durante

- Economico

- Condizioni economiche

- economie

- economia

- sforzi

- altrove

- Etere (ETH)

- Europa

- Anche

- eccezione

- eccesso

- ha spiegato

- estensione

- fatto

- fabbriche

- Svanisce

- Caduta

- finanziario

- crisi finanziaria

- ricerca

- Nel

- fragilità

- da

- ulteriormente

- Germania

- globali

- finanziaria globale

- Crisi finanziaria globale

- maggiore

- Avere

- Eroe

- superiore

- Highlight

- mettendo in evidenza

- storicamente

- Tuttavia

- HTTPS

- impatto

- miglioramento

- miglioramento

- in

- Aumento

- Index

- India

- indica

- indicando

- indicativo

- industria

- SUO

- Jamie

- Gennaio

- Giappone

- jpg

- giugno

- Le

- Lavoro

- atterraggio

- grandi

- maggiore

- minore

- Livello

- livelli

- Leva

- a

- inferiore

- minore

- Produttori

- consigliato per la

- industria manifatturiera

- Mercati

- Materiale

- Impulso

- Mese

- mensile

- molti

- no

- Nord

- America del Nord

- notevole

- segnatamente

- ottobre

- of

- Olio

- on

- esclusivamente

- minimo

- ordini

- nostro

- Pace

- particolarmente

- eseguire

- Platone

- Platone Data Intelligence

- PlatoneDati

- punto

- in bilico

- conservazione

- Presidente

- Prezzi

- produrre

- fornisce

- acquisto

- Crudo

- recente

- recessione

- regione

- parente

- rimanere

- resti

- rapporto

- Report

- elasticità

- Aumento

- crescita

- ROSE

- Correre

- running

- s

- sembra

- visto

- Settembre

- la carenza di

- Spettacoli

- significativamente

- Segni

- simile

- da

- allentato

- Soft

- Spot

- rigido

- costante

- Ancora

- più forte

- fortemente

- sostanziale

- tale

- suggerire

- fornitore

- fornitori

- fornire

- supply chain

- Catene di fornitura

- Indagine

- sostenuta

- di

- che

- I

- il mondo

- loro

- Là.

- di

- questo

- a

- Tracking

- trasporti

- tipico

- Uk

- us

- Economia americana

- Ve

- vice

- Vicepresidente

- Volatilità

- Prima

- we

- debolezza

- Settimane

- è andato

- Occidentale

- Europa occidentale

- Che

- quale

- while

- con

- lavoratori

- mondo

- In tutto il mondo

- zefiro